Tube Laser Cutting In Toledo, Ohio

Applications Across Industries

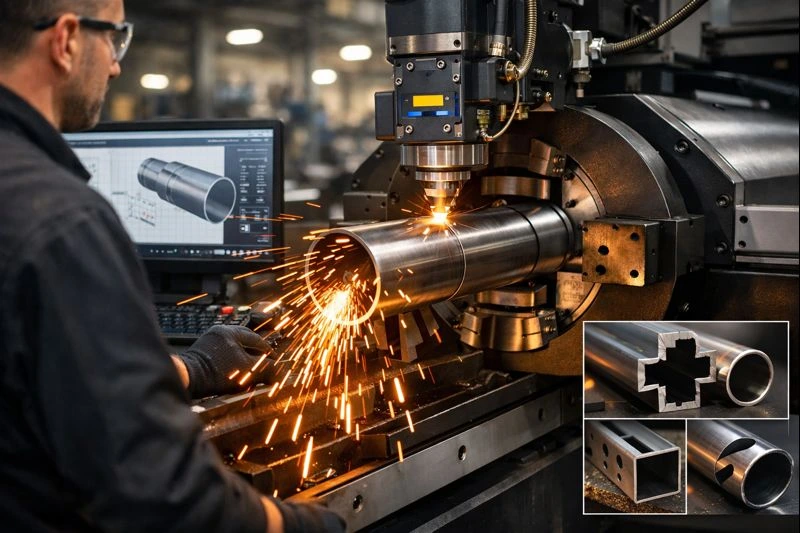

What is Tube Laser Cutting?

At its core, laser tube cutting is a thermal cutting process that utilizes a focused beam of high-energy light to melt and vaporize material. Unlike flat sheet lasers, a tube laser cutting machine is specifically designed to handle three-dimensional profiles. These machines rotate the tube while the cutting head moves along the length of the material, allowing for intricate cuts on round, square, rectangular, and even oval-shaped tubes.

The beam generated by the machine is incredibly narrow, which allows for tight tolerances that mechanical cutting simply cannot match. Because the process is non-contact, there is no mechanical force applied to the tube, eliminating the risk of warping or deforming the material during the cut.

This technology is controlled by advanced CNC (Computer Numerical Control) software. Operators upload 3D CAD designs directly to the machine, which then executes the cut with microscopic precision. This digital-to-physical workflow eliminates the need for expensive hard tooling or custom dies, making it a flexible solution for both prototypes and large-scale production.

Welding Excellence That Delivers Results

Pre-owned machines

Reliable pre-owned machines for metal tapping, offering quality performance at great prices.

Technical Service

Expert solutions ensuring precision, reliability, and efficiency in metal fabrication.

Spare parts

High-quality spare parts for metal tapping to ensure efficient performance and smooth operation.

Our Tube Laser Cutting Services

We pride ourselves on offering comprehensive tube laser cutting services tailored to the specific needs of Toledo businesses. Our capabilities extend far beyond simple cut-to-length jobs. We provide a full spectrum of fabrication solutions designed to solve complex engineering challenges.

Custom Tube Fabrication

Every project has unique requirements. We specialize in custom fabrication where off-the-shelf components simply won’t work. Whether you need specific slotting for joinery or complex coping for welded assemblies, our equipment can handle the geometry.

Prototyping and Production Runs

One of the biggest advantages of laser tube cutting services is scalability. Because there is no tooling to create, we can produce a single prototype for design verification in the morning and switch to a production run of thousands of units by the afternoon. This flexibility helps you bring products to market faster.

Cutting Complex Designs and Shapes

Traditional drilling and milling have limitations regarding shape. Lasers do not. We can cut intricate patterns, logos, alphanumeric identification tags, and complex joint geometries directly into the tube wall. This capability often allows designers to rethink how parts fit together, utilizing tab-and-slot designs that make downstream assembly and welding much faster.

Material Versatility

Our state-of-the-art machinery handles a wide variety of materials. We routinely process:

- Carbon Steel: The backbone of structural applications.

- Stainless Steel: Ideal for food processing, medical, and architectural use.

- Aluminum: Lightweight and corrosion-resistant, perfect for aerospace and automotive.

- Brass and Copper: Often used for decorative or conductive applications.

How We Provide Our Tube Laser Cutting Services

Delivering high-quality parts requires more than just owning a machine; it requires a disciplined workflow. We have refined our process to ensure that from the moment you contact us to the moment your parts are delivered, the experience is seamless.

1. Consultation and Design Review

The process begins with understanding your goals. We review your CAD files and engineering drawings. Our team often identifies opportunities to optimize the design for the tube laser cutting machine, suggesting changes that could save material or reduce cutting time without compromising structural integrity.

2. Precision Cutting

Once the design is finalized, our skilled technicians program the equipment. We utilize nesting software that arranges the parts on the raw tube stock to maximize yield and minimize scrap. The laser tube cutting process then runs automatically, cutting features, holes, and end profiles in a single pass.

3. Quality Control and Inspection

Precision is our promise. We don’t rely on guesswork. Our quality control team uses advanced measurement tools to verify that every dimension meets your specifications. We check for cut quality, dimensional accuracy, and surface finish.

4. Delivery and Support

Located right here in Toledo, Ohio, we offer convenient logistics for local partners. We ensure your parts are packaged securely to prevent damage during transit. Our support doesn’t end at delivery; we remain available to discuss future iterations or adjustments for upcoming production runs.

Advantages of Tube Laser Cutting

Why are so many manufacturers moving away from saws and drills in favor of lasers? The advantages are quantifiable and significantly impact the bottom line.

High Precision and Accuracy

A tube laser cutting machine operates with tolerances often measured in the thousandths of an inch. This repeatability ensures that the thousandth part looks exactly like the first. For assembly lines that rely on robotic welding or tight-fit fixtures, this consistency is non-negotiable.

Clean Edges and Minimal Finishing

Mechanical cutting methods often leave behind sharp burrs or rough edges that require manual grinding—a time-consuming and expensive secondary operation. Laser cutting produces a clean, sealed edge that is safe to handle and ready for welding or powder coating immediately off the machine.

Reduced Material Waste

Raw material costs are a significant portion of any manufacturing budget. Our advanced software “nests” parts tightly together, leaving minimal gaps between them. This efficiency means we get more parts out of every stick of tubing, saving you money on material costs.

Faster Turnaround

Traditional fabrication might require a tube to be moved from a saw to a drill press, then to a milling machine, and finally to a deburring station. Tube laser cutting consolidates all these operations into one cycle. This consolidation drastically reduces the total processing time, allowing us to deliver your parts sooner.

Design Innovation

Designers are often limited by manufacturing constraints. Laser cutting removes those shackles. You can design complex, self-fixturing assemblies (like tubes that bend by hand and lock into place) that reduce the need for welding jigs.

Why Choose Us for Laser Tube Cutting in Toledo

Toledo has a rich history of industry and manufacturing, and we are proud to contribute to that legacy. Choosing the right partner for your laser tube cutting services is about finding a team that cares as much about your project as you do.

Experienced Technicians: Our operators are not just button-pushers; they are skilled tradespeople who understand metallurgy and machine dynamics. They know how to tweak parameters to get the best edge quality on difficult materials.

State-of-the-Art Technology: We invest heavily in the latest tube laser cutting machines. This investment ensures we can cut faster, thicker, and more accurately than competitors relying on older technology.

Quick Turnaround: We understand that a missing part can shut down an entire assembly line. Our efficient workflow allows us to offer competitive lead times, ensuring your project stays on schedule.

Commitment to Quality: We believe that quality is not an accident; it is the result of high intention and intelligent execution. Our track record in serving multiple industries speaks to our reliability.

Industries We Serve

The versatility of tube laser cutting makes it an essential service across a broad spectrum of sectors.

Automotive and Aerospace

Weight reduction and strength are critical in these fields. We produce high-strength steel chassis components, roll cages, exhaust components, and aluminum structural frames that meet strict safety standards.

Construction and Architecture

From structural support beams to decorative handrails, our cuts are used in buildings across Ohio. The ability to cut complex copes allows for seamless connections in truss systems and aesthetic frameworks.

Industrial Machinery

Manufacturers of conveyors, agricultural equipment, and packaging machinery rely on us for heavy-duty frames and precision mechanical components. The accuracy of our cuts ensures their machines run smoothly and last longer.

Furniture and Interior Design

Modern industrial furniture relies heavily on metal tubing. We create custom legs, frames, and supports for tables, chairs, and shelving units. The clean finish of the laser cut is perfect for high-visibility consumer products.

Comparison: Laser Tube Cutting vs. Traditional Methods

To fully appreciate the value of our services, it helps to compare them directly against older fabrication methods.

Mechanical Sawing: While effective for simple cut-to-length jobs, sawing exerts physical pressure on the tube, which can cause deformation. It leaves burrs that must be removed, and it cannot cut holes or slots.

Drilling and Milling: Adding holes to a tube after sawing requires moving the part to a separate machine. This adds labor cost and introduces the potential for human error in positioning. Tube laser cutting creates holes in the same step as the cut-off, ensuring perfect relative positioning.

Plasma Cutting: While plasma is faster than sawing, it lacks the precision of a laser. It introduces a large heat-affected zone (HAZ) which can warp thinner tubes and leave a messy edge that requires significant cleanup.

In contrast, laser technology offers the “trifecta” of manufacturing: speed, precision, and efficiency. It creates a superior product at a competitive price point by eliminating secondary labor.

How to Get Started

Ready to improve your manufacturing process? Getting a quote for your project is simple.

- Contact Us: Reach out via our website form, email, or phone.

- Submit Your Drawings: Send us your CAD files or prints.

- Receive Your Quote: We will provide a detailed estimate including material costs and lead times.

We offer free project assessments to help you determine if laser cutting is the right solution for your specific application.

Frequently Asked Questions

What is the maximum diameter tube you can cut?

Our tube laser cutting machine can handle a wide range of diameters, typically up to 8-10 inches for round tubes and comparable dimensions for square and rectangular profiles. Please contact us with specific dimensions for verification.

Can you cut already painted or coated tubes?

Yes, laser cutting can be performed on coated materials, though settings may need to be adjusted to ensure the coating doesn’t interfere with the cut quality or optics.

Do I need to provide a 3D CAD file?

While a 3D CAD file (such as STEP or IGES) is the most efficient way to get started, our team can work from 2D drawings or even hand sketches to help create the necessary digital files for production.

Is laser cutting expensive compared to sawing?

For simple straight cuts, sawing may be cheaper. However, as soon as you add holes, slots, or complex angles, tube laser cutting becomes significantly more cost-effective because it eliminates the labor cost of drilling, milling, and deburring.

Elevate Your Project with Precision Fabrication

The difference between a good product and a great one often lies in the quality of its components. By choosing tube laser cutting in Toledo, Ohio, you are investing in precision, efficiency, and reliability.

Whether you are looking to prototype a new invention or streamline a mass-production run, our team is ready to help. We combine advanced technology with local expertise to deliver results that exceed expectations. Don’t let outdated fabrication methods slow you down.

Contact us today to request a quote and see the difference precision makes.

Join us

Fill out the form and our admission experts will respond within 24 hours to guide you through your study abroad journey.

address

444 W. Laskey Road, Suite V, Toledo, OH.

contact

We're Here to Help

Fill out the form below to get in touch with us for inquiries, support, or more information.