Choosing the Right Metal for Your Fabrication Project

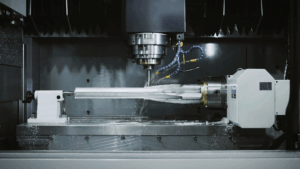

When it comes to metal fabrication, one of the most critical decisions you’ll make is choosing the right type of metal for your project. Whether you’re working on structural components, machinery, or decorative features, the material you select will directly impact the quality, functionality, and durability of your final product.

In any metal fabrication process, the goal is to produce strong, precise, and reliable metal parts. However, not all metals are created equal. Each type of metal has its own unique properties that make it more or less suitable for specific applications especially when processes like metal tapping and bending are involved.

Understanding Your Project Requirements

Before selecting a metal, it’s essential to consider your project’s specific requirements. Will the metal parts need to withstand high stress, extreme temperatures, or corrosive environments? Will they be exposed to the elements? Will they need to support heavy loads, or is weight reduction a priority? The answers to these questions help guide the choice of metal during the metal fabrication process.

Common Metals Used in Fabrication

- Steel – Known for its strength and versatility, steel is a popular choice in metal fabrication. It’s ideal for load-bearing structures and is easy to weld, cut, and shape. Steel also handles bending and metal tapping well, making it a go-to for many industrial applications.

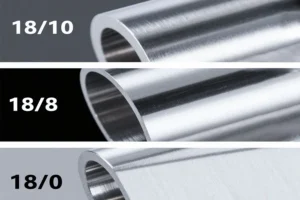

- Stainless Steel – Resistant to corrosion and attractive in appearance, stainless steel is commonly used in kitchens, hospitals, and exterior architectural features. It’s durable, though it can be tougher to work with in bending and metal tapping operations compared to other metals.

- Aluminum – Lightweight yet strong, aluminum is perfect for projects that require reduced weight without compromising strength. It’s also corrosion-resistant and performs well in bending, though it requires more care during metal tapping due to its softer nature.

- Copper – Excellent for electrical and decorative applications, copper offers high conductivity and a unique look. However, it’s more expensive and is best used in specialized metal fabrication projects.

Importance of Fabrication Techniques

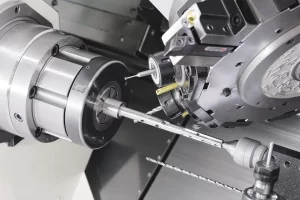

The metal you choose must be compatible with the techniques required to shape and finish your project. Processes like metal tapping (cutting threads into holes for screws or bolts) and bending (shaping metal without breaking it) are vital in creating functional and precise metal parts.

Some metals are easier to tap and bend than others. For example, mild steel handles bending and metal tapping well, making it suitable for custom brackets or enclosures. Softer metals like aluminum are easy to bend but require precision during tapping to avoid stripping threads.

Cost and Availability

Budget also plays a role in material selection. While some high-performance metals offer exceptional benefits, they can increase the overall cost of your metal fabrication project. Balancing cost with performance is key to achieving optimal results without overspending.

Final Thoughts

Choosing the right metal is essential for successful metal fabrication. From the strength and durability of steel to the lightweight versatility of aluminum, each material brings unique advantages to the table. When selecting materials, always consider the application, environment, and how the metal will respond to bending, metal tapping, and other fabrication techniques.

With the right metal and skilled fabrication, you can produce high-quality metal parts that meet your project goals efficiently and cost-effectively.