Selecting the right sheet metal brake service provider is one of the most important decisions you can make in any metal fabrication project. Whether you work in construction, HVAC, manufacturing, or custom metal design, the accuracy of each bend determines the overall quality of the finished product. A bend that is even slightly off can create problems with fit, alignment, and structural performance, which often leads to extra costs and wasted time.

Because of this, choosing a skilled and reliable partner for your sheet metal brake needs is essential. In this guide, you will learn what sheet metal brake services include, the qualities you should always look for in a provider, and why many businesses trust Toledo Fab for dependable metal bending solutions.

Understanding Sheet Metal Brake Services

A sheet metal brake is a machine used to bend and form metal sheets into specific shapes. You may hear similar terms like sheet metal brake, sheet metal bending brake, metal sheet metal brake, or metal sheet brake. All of these refer to equipment designed to create clean, consistent, and accurate bends.

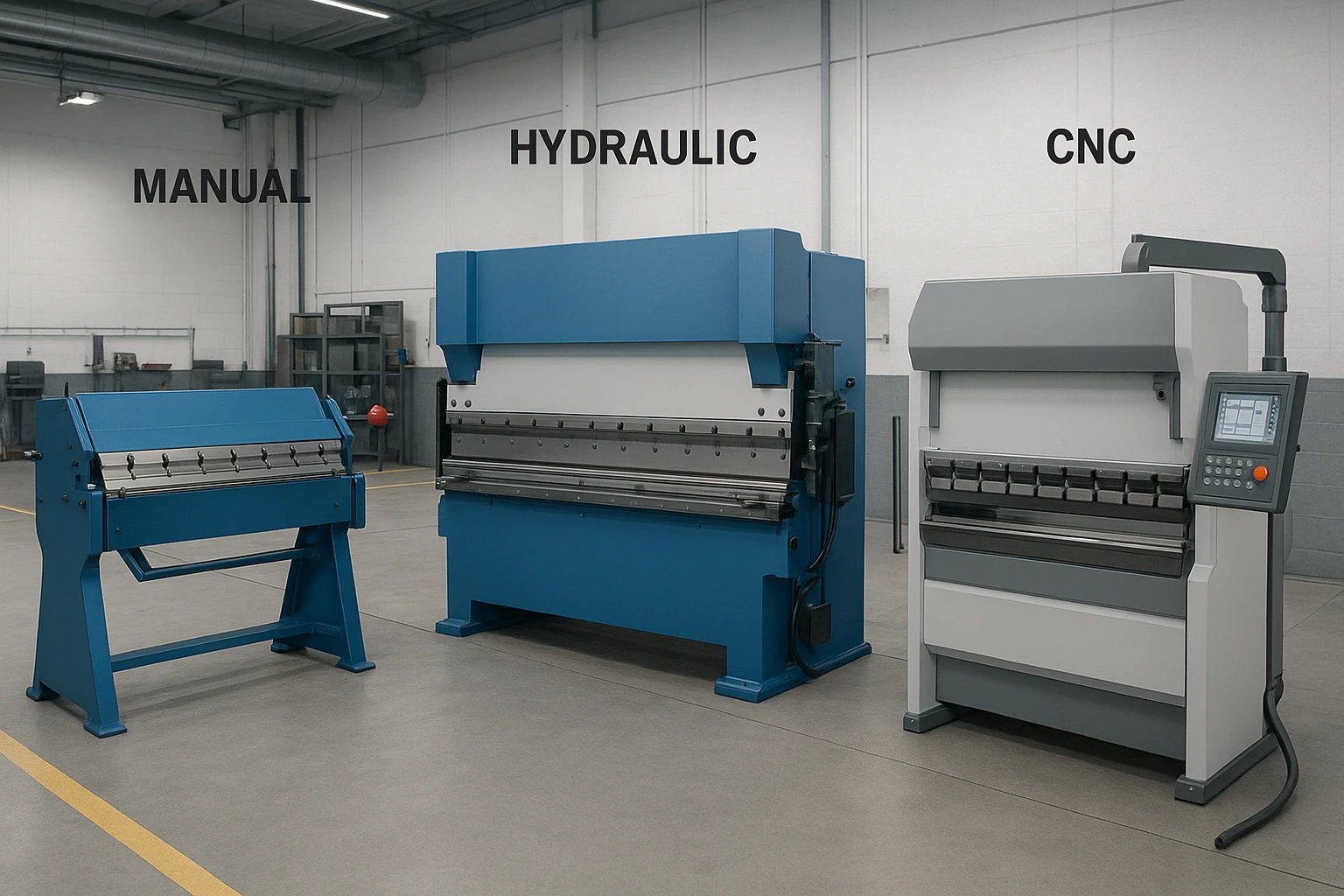

Sheet metal brake machines come in different types

Manual brakes used for small projects and lighter materials

Hydraulic brakes used for thicker metal and larger workloads

CNC brakes used for precise, repeatable, computer controlled bending

A good service provider does more than simply operate the machine. They understand material behavior, bending angles, structural requirements, and the correct tools needed to achieve accurate results. This combination of equipment and expertise is what makes sheet metal brake services so valuable.

Why the Right Provider Makes a Difference

Even though bending metal may look straightforward, it requires skill and attention to detail. A small mistake in the bend angle or measurement can cause large problems later in the project. If the part does not fit correctly or align properly during installation, you may face delays or the need to start over.

Choosing a reliable provider ensures

Clean and precise bends

Fewer mistakes and less wasted material

Faster production times

Better strength and appearance

Reduced rework and lower overall costs

Working with the right team gives you confidence that every part will be completed accurately the first time.

Key Qualities to Look For in a Sheet Metal Brake Service Provider

1. Experience and Technical Knowledge

Experience is one of the strongest signs of reliability. A company that has worked with many industries understands how different metals react to bending and knows how to avoid bending errors.

Before choosing a provider, ask yourself

Have they handled projects similar to yours

Do they understand the material you are using

Do they offer professional sheet metal brake services regularly

A provider with strong experience is more likely to produce consistent and accurate results.

2. Quality of Equipment

High quality equipment is essential for high quality bending. A dependable provider should use well maintained machines capable of handling both simple and complex projects.

This includes

Manual brakes for small or simple bends

Hydraulic brakes for thicker metals

CNC brakes for precise and repeated bending

If your project needs long sheets or heavy gauge metal, the provider must have machines designed for that level of work. Equipment capability directly affects the accuracy of your final product.

3. Knowledge of Different Materials

Different metals need different bending techniques. For example

Stainless steel requires more force

Aluminum can crack if bent incorrectly

Galvanized metal has special considerations

Copper and brass need gentle handling

A skilled provider understands these differences and uses the right tools and bending methods for each material. This prevents cracks, distortions, and weak points in the final product.

Before choosing a provider, confirm they regularly handle the material required for your project.

4. Precision and Accuracy

Precision is one of the most important reasons to choose professional sheet metal brake services. Even small inaccuracies can cause misalignment, poor fit, or problems during installation.

A dependable provider should offer

Tight tolerances

Smooth and clean bends

High repeatability for large orders

A strong quality control process

When a shop maintains a clear inspection process and verifies each bend carefully, your final product will always meet expectations.

5. Fast and Reliable Turnaround Times

Timelines are important in nearly every industry. Even high quality work becomes a problem if it takes too long to complete. Your provider should have an efficient process that ensures both speed and accuracy.

Before choosing a provider, ask

What is their standard turnaround time

Do they offer rush order services

How do they handle urgent or complex jobs

A reliable and organized team keeps your project moving without sacrificing quality.

6. Customization and Flexibility

Not every project is standard. Sometimes you need custom shapes, unique angles, or one of a kind parts. A good provider should offer flexibility and the ability to handle both simple and complex jobs.

Look for a provider who supports

Custom prototypes

One time solutions

Large production runs

Detailed or unusual bending requirements

The more flexible the provider, the easier your project will be.

7. Clear Communication and Great Support

Good communication is essential in any partnership. A provider should be easy to reach, willing to answer questions, and able to explain what they can deliver.

You should expect

Clear explanations

Fast responses

Transparent pricing

Helpful guidance and recommendations

A provider who communicates well helps prevent misunderstandings and ensures the final result matches your vision.

Mistakes to Avoid When Choosing a Sheet Metal Brake Provider

To make the best choice, avoid these common mistakes

Selecting a provider based only on the lowest price

Ignoring what equipment they use

Not checking their industry experience

Skipping sample or prototype testing

Choosing a provider just because they offer the cheapest price can often lead to poor results and expensive rework later.

Why Toledo Fab Is a Trustworthy Choice for Sheet Metal Brake Services

Toledo Fab is known for reliable, accurate, and professional sheet metal brake services. Many businesses rely on Toledo Fab because of the company’s attention to detail and commitment to high quality results.

Modern and Accurate Equipment

Toledo Fab uses advanced sheet metal brake machines that produce clean, smooth, and consistent bends. These include manual, hydraulic, and CNC equipment to support a wide variety of projects.

Experienced and Skilled Technicians

The technicians at Toledo Fab understand how metals behave and how to bend them properly. Their skill ensures that every part is made with precision.

Strong Quality Standards

Toledo Fab maintains tight tolerances and performs detailed inspections to ensure the highest quality in every bend. Whether you need a single part or a large order, you can expect consistent results.

Fast and Efficient Service

The team at Toledo Fab understands the importance of deadlines. With efficient processes and skilled staff, your project can be completed quickly without sacrificing quality.

Custom Solutions for Any Project

Toledo Fab offers flexible services for simple parts, complex bends, prototypes, and custom designs. No matter your challenge, the team is ready to help.

Conclusion

Choosing the right sheet metal brake service provider is one of the most important steps in any metal fabrication project. When you focus on experience, equipment quality, material knowledge, precision, communication, and flexibility, you can confidently select a provider who delivers great results.

If you are looking for a trusted partner with strong sheet metal brake, sheet metal bending brake, metal sheet metal brake, and metal sheet brake capabilities, Toledo Fab is ready to support you. Contact Toledo Fab today to request a quote or discuss your project with our team.