Metal fabrication plays a vital role in shaping the modern world. From towering buildings and industrial machinery to everyday commercial structures, fabricated metal components are everywhere. Understanding what metal fabrication is and how it works helps businesses, contractors, and decision makers choose the right solutions for their projects. This guide explains metal fabrication in simple terms, explores its main types, and highlights why professional fabrication services are essential across industries.

At its core, metal fabrication involves transforming raw metal materials into functional parts or structures through cutting, forming, welding, and finishing processes. It supports a wide range of industries, including construction, manufacturing, energy, automotive, and agriculture. Without metal fabrication, many of the products and structures we rely on would not exist.

This article covers what is metal fabrication, explains the connection between metal fabrication and welding, and breaks down the major types of metal fabrication such as industrial, structural, commercial, and custom fabrication. You will also learn what sheet metal fabrication involves, what a metal fabricator does, and how to choose the right metal fabrication company for your needs.

What Is Metal Fabrication?

What is metal fabrication is a common question for anyone new to the industry. In simple terms, metal fabrication is the process of creating metal structures and components by shaping, cutting, and assembling raw metal materials. These materials are transformed into finished products that are used in buildings, machinery, infrastructure, and countless industrial applications.

The metal fabrication process typically begins with a design. Engineers or designers create drawings or digital models that define the shape, dimensions, and specifications of the final product. Once the design is approved, the fabrication process moves into production.

Cutting is the first major step. Metal sheets, plates, or bars are cut into specific sizes using tools such as laser cutters, plasma cutters, or saws. After cutting, the metal is formed into the required shape through bending, rolling, or pressing. Forming allows flat metal pieces to become angles, curves, or complex shapes.

Welding then joins individual metal components together to create a strong and unified structure. After welding, finishing processes such as grinding, polishing, or coating are applied to improve appearance, corrosion resistance, and durability.

Common metals used in fabrication include steel, stainless steel, aluminum, and other alloys. Unlike general manufacturing, which may involve mass production of consumer goods, metal fabrication focuses on custom or semi custom metal components designed for specific applications.

What Is Metal Fabrication and Welding?

What is metal fabrication and welding is another important concept to understand. While metal fabrication includes many processes, welding plays a central role in assembling fabricated components. Welding is the method used to permanently join metal parts together using heat and sometimes pressure or filler material.

In metal fabrication, welding ensures that separate components become a single strong structure. Without welding, many fabricated products would lack the strength and stability required for real world use. Welding is commonly used in structural frameworks, industrial equipment, and commercial installations.

Several welding techniques are used in metal fabrication. MIG welding is often used for its speed and versatility, making it suitable for large projects. TIG welding offers precise control and clean welds, which is ideal for stainless steel and aluminum. Stick welding is commonly used for heavy duty applications and outdoor work.

The quality of welding directly affects the safety and durability of fabricated metal products. Poor welds can lead to structural failures, safety hazards, and costly repairs. That is why skilled welders and strict quality control are essential parts of professional metal fabrication services.

Types of Metal Fabrication

Metal fabrication can be divided into several categories based on the type of products being created and their intended use. Understanding these types helps determine the right fabrication approach for a specific project.

Industrial Metal Fabrication

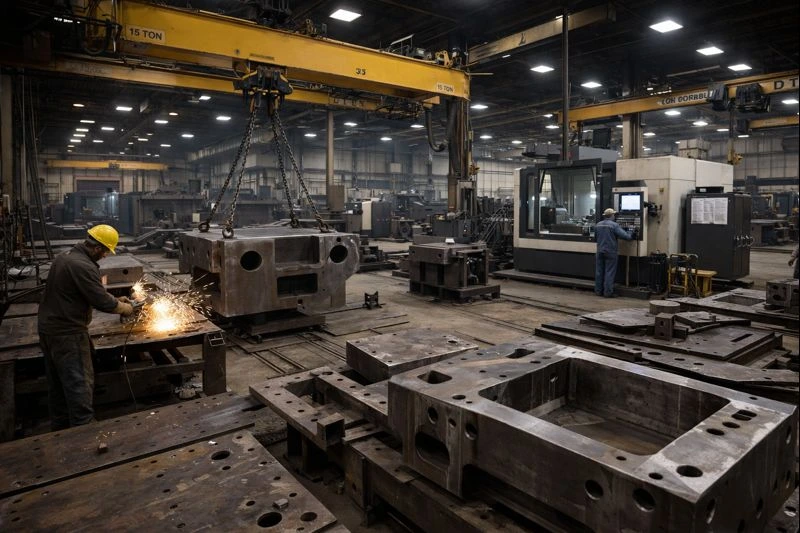

Industrial metal fabrication focuses on producing heavy duty metal components used in industrial environments. These components are designed to withstand high stress, extreme temperatures, and continuous operation.

Industrial fabrication often involves thick metal materials and complex assemblies. Components such as machinery frames, equipment enclosures, platforms, tanks, and supports are commonly produced through industrial metal fabrication. Precision and durability are critical, as even small errors can affect performance and safety.

Industries that rely heavily on industrial metal fabrication include manufacturing, energy, automotive, and processing plants. In these settings, fabricated metal components must meet strict specifications and quality standards to ensure long term reliability.

Structural Metal Fabrication

Structural metal fabrication involves creating metal frameworks that support buildings and infrastructure. This type of fabrication is essential in both commercial and residential construction projects.

Structural components such as beams, columns, frames, and platforms are fabricated to provide strength and stability. These elements form the skeleton of buildings, bridges, and other structures. Structural metal fabrication requires careful engineering to ensure load bearing capacity and compliance with building codes.

Welding plays a major role in structural fabrication, as strong welds are necessary to connect large metal components. Quality testing and inspections are performed to verify the integrity of the fabricated structure before installation.

Commercial Metal Fabrication

Commercial metal fabrication focuses on metal products used in public, business, and retail spaces. These products often require a balance between strength, functionality, and appearance.

Typical commercial fabrication products include staircases, railings, awnings, shelving, and architectural metal features. Unlike industrial fabrication, commercial projects often emphasize visual appeal in addition to durability.

Custom designs are common in commercial metal fabrication because each space has unique requirements. Fabricators must work closely with designers and clients to create metal solutions that meet both functional and aesthetic goals.

Custom Metal Fabrication for Industrial, Structural, and Commercial Needs

Custom metal fabrication refers to tailored solutions designed to meet specific project requirements. Instead of using standard components, custom fabrication allows for complete flexibility in design, materials, and finishes.

Custom projects often involve detailed design work, prototyping, and close collaboration between the client and the fabricator. This approach is ideal for unique applications where standard solutions are not suitable.

The benefits of custom metal fabrication include precise fit, improved performance, and the ability to address complex challenges. Whether for industrial machinery, structural frameworks, or commercial installations, custom fabrication ensures that the final product aligns perfectly with the intended use.

What Is Sheet Metal Fabrication?

What is sheet metal fabrication is another key area within the broader metal fabrication industry. Sheet metal fabrication focuses on working with thin metal sheets, typically made from steel, stainless steel, or aluminum.

Sheet metal fabrication involves cutting, bending, and forming flat metal sheets into functional components. Common processes include laser cutting, punching, bending, and welding. These methods allow fabricators to produce lightweight yet strong parts with high precision.

Sheet metal fabrication supports industrial, structural, and commercial fabrication projects. In industrial settings, sheet metal is used for enclosures, panels, and equipment housings. In structural applications, it may be used for cladding and architectural elements. Commercially, sheet metal is often found in HVAC systems, cabinets, and decorative features.

Because sheet metal is versatile and cost effective, it is widely used across industries. Professional sheet metal fabrication ensures accurate dimensions, clean finishes, and consistent quality.

What Is a Metal Fabricator? Roles and Responsibilities

What is a metal fabricator refers to the skilled professional or company responsible for carrying out the metal fabrication process. A metal fabricator works with raw metal materials to create finished products based on design specifications.

The responsibilities of a metal fabricator include reading blueprints, selecting appropriate materials, operating fabrication equipment, and performing cutting, forming, and welding tasks. Fabricators must ensure that each component meets quality standards and project requirements.

Metal fabricators use a variety of tools and machinery, including CNC machines, laser cutters, press brakes, and welding equipment. Their expertise allows them to produce accurate and reliable metal components.

It is important to distinguish between a metal fabricator and a welder. While welding is a critical skill, metal fabrication encompasses a broader range of processes beyond welding alone. A professional fabricator understands the entire workflow from design to finishing.

Industries That Rely on Metal Fabrication

Metal fabrication supports a wide range of industries that depend on durable and custom metal components.

The construction industry relies on metal fabrication for structural frameworks, supports, and architectural elements. Manufacturing uses fabricated metal parts for machinery, tools, and production systems. The automotive industry depends on fabricated components for vehicle frames, panels, and assemblies.

Energy and infrastructure projects use metal fabrication for pipelines, platforms, and support structures. Agriculture relies on fabricated metal equipment and storage solutions. Across all these industries, metal fabrication provides strength, reliability, and adaptability.

Benefits of Professional Metal Fabrication Services

Working with professional metal fabrication services offers many advantages. Precision and consistency ensure that components meet exact specifications and perform as intended. Structural integrity is improved through proper material selection and skilled welding.

Professional fabrication services also enhance cost efficiency by reducing material waste and minimizing rework. Customization allows projects to be tailored to specific needs, improving functionality and performance. Long term durability ensures that fabricated components withstand environmental and operational stresses.

Choosing experienced fabricators leads to higher quality results and greater confidence in the finished product.

How to Choose the Right Metal Fabrication Company

Selecting the right metal fabrication company is essential for project success. Experience in industrial, structural, and commercial metal fabrication indicates the ability to handle diverse requirements. Reviewing a company’s portfolio helps assess the quality and complexity of previous projects.

Certifications, safety standards, and quality control processes reflect a commitment to professional practices. Modern fabrication technology and skilled metal fabricators contribute to accuracy and efficiency.

Communication is another key factor. A reliable fabrication company will collaborate closely with clients, offer customization options, and provide ongoing project support. Working with established providers such as Toledo Fab reflects how experienced fabrication companies combine technical expertise, reliable processes, and customer focused service to support successful metal fabrication projects.

Conclusion

Understanding what is metal fabrication helps clarify its importance in today’s industries. From industrial machinery and structural frameworks to commercial installations, metal fabrication provides the foundation for countless applications.

By exploring metal fabrication and welding, learning about sheet metal fabrication, and understanding the role of a metal fabricator, it becomes clear why professional fabrication services matter. Choosing the right fabrication partner ensures quality, safety, and long term value for any project.

Metal Fabrication FAQs

What is metal fabrication?

Metal fabrication is the process of shaping, cutting, and assembling metal to create functional components and structures.

What is sheet metal fabrication?

Sheet metal fabrication involves working with thin metal sheets to produce parts through cutting, bending, and forming processes.

What is metal fabrication and welding?

Metal fabrication includes multiple processes, with welding being the method used to join metal components into a unified structure.

What does a metal fabricator do?

A metal fabricator creates metal products by operating fabrication equipment and following design specifications.

What industries use metal fabrication?

Industries such as construction, manufacturing, automotive, energy, agriculture, and infrastructure rely heavily on metal fabrication.