Look around you. From the steel skeleton of the office building you work in to the chassis of the car you drive, and even the chair you are likely sitting on, metal is the backbone of modern civilization. But metal alone isn’t enough; it needs to be shaped, connected, and secured. This is where the importance of welding becomes undeniable.

Welding is far more than just a method for sticking two pieces of metal together. It is a foundational industrial process that ensures the safety, durability, and functionality of the infrastructure and products we rely on daily. As industries evolve and engineering demands become more complex, the role of welding in manufacturing continues to expand. It offers a permanent, high-strength joining method that mechanical fastening simply cannot match.

In this comprehensive guide, we will explore why welding is critical to industries ranging from aerospace to construction. We will examine the various techniques used today, the role of skilled labor versus automation, and why understanding the importance of welding is essential for anyone involved in metal fabrication.

What Is Welding and Why Does It Matter?

At its core, welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. This is distinct from lower-temperature techniques such as brazing and soldering, which do not melt the base metal.

The true value of this process lies in the molecular bond it creates. When two pieces of metal are bolted or riveted, they are mechanically fastened. They are held together by friction and shear strength, but they remain two separate pieces. Welding, however, fuses the materials at a molecular level, effectively turning two parts into a single, monolithic structure.

This fusion is why the welding process remains the gold standard for creating joints that need to withstand immense pressure, vibration, and environmental stress. Whether it is a pipeline carrying high-pressure gas or a ship navigating rough seas, welding provides the continuity and strength required for long-lasting metal structures.

Historical Evolution and Growing Importance of Welding

The history of metal joining dates back to the Bronze Age, but the importance of welding as we know it began to take shape during the Industrial Revolution. Early blacksmiths used forge welding—heating metal until it was red hot and hammering it together—to create tools and weapons. While effective for the time, this labor-intensive method could not keep up with the demands of mass production.

The discovery of the electric arc in the 19th century paved the way for modern welding. World War I and II drastically accelerated welding technology, as nations needed to build ships, tanks, and aircraft faster and lighter than ever before. Riveting, which added unnecessary weight and labor, was largely replaced by arc welding.

Today, the importance of welding has increased alongside modern engineering demands. As we push the boundaries of architecture with taller skyscrapers and explore new frontiers in space, the need for lighter, stronger, and more heat-resistant joints has driven the development of advanced techniques like laser and electron beam welding. The evolution of welding is the evolution of modern industry itself.

Importance of Welding in the Metal Fabrication Process

Metal fabrication is a broad term that encompasses the entire process of building machines and structures from raw metal materials. It typically involves cutting, bending, and assembling. While cutting and bending give the metal its shape, welding is the critical step that brings it all together.

Understanding the importance of welding in metal fabrication requires looking at the workflow. A fabricator might laser-cut steel plates with extreme precision and bend them into complex angles, but without high-quality welding, those parts are just a collection of loose components. Welding transforms these disparate parts into a functional load-bearing structure.

Furthermore, the accuracy of the weld dictates the performance of the final product. A poor weld can distort the metal due to excessive heat input, ruining the dimensional accuracy of a fabricated assembly. Conversely, precise welding ensures that the final product meets strict tolerances. In the fabrication ecosystem, welding is the bridge between a design concept and a tangible, functional reality.

Key Reasons Highlighting the Importance of Welding

Why do engineers and architects choose welding over bolts, rivets, or adhesives? The answer lies in five distinct advantages that underscore the importance of welding in heavy industry.

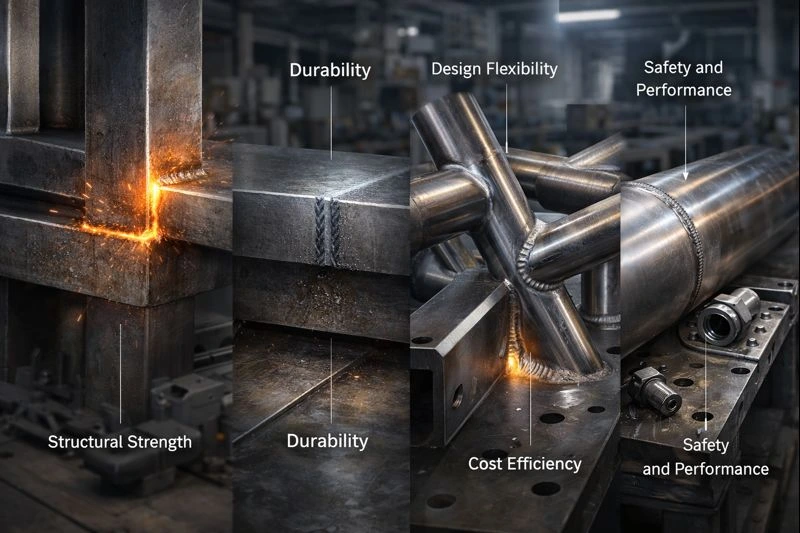

Structural Strength and Load-Bearing Capability

Welded joints are often stronger than the base metal itself. Because the process fuses the materials, there are no holes drilled for fasteners, which can create weak points or stress risers in a structure. This makes welding indispensable for heavy-duty applications where structural failure is not an option.

Durability and Long-Term Reliability

Mechanical fasteners can loosen over time due to vibration. A welded joint, however, is permanent. It creates a sealed connection that is resistant to fatigue and vibration. Additionally, because there are no gaps between the joined materials, welded structures are less prone to rust and corrosion that often occur in the crevices of bolted joints.

Design Flexibility and Customization

Welding allows for the creation of complex shapes and seamless designs that would be impossible or incredibly expensive with casting or mechanical assembly. It gives designers the freedom to use tubes, plates, and angles in any configuration, enabling high levels of customization.

Cost Efficiency in Fabrication

Welding is often more cost-effective than other assembly methods. It reduces the weight of the structure by eliminating heavy connecting plates and hundreds of bolts. It also reduces material waste and speeds up the assembly process, translating to lower labor and material costs.

Safety and Performance

In critical applications like pressure vessels or nuclear reactors, a leak could be catastrophic. Welding provides a leak-proof, airtight seal that ensures safety and performance standards are met.

Types of Welding That Demonstrate Its Importance

There is no single “best” welding method; rather, different techniques highlight the importance of welding across various applications.

MIG Welding and Its Industrial Significance

Gas Metal Arc Welding (GMAW), commonly known as MIG, is valued for its speed and versatility. It uses a continuous wire feed, making it ideal for long, continuous welds. It is the workhorse of the manufacturing world, used extensively in automotive and general fabrication.

TIG Welding for Precision Fabrication

Gas Tungsten Arc Welding (GTAW), or TIG, is the choice for high-precision work. It requires a high level of skill but produces clean, aesthetically pleasing welds. It is critical for welding thin sections of stainless steel and non-ferrous metals like aluminum and magnesium, often used in aerospace and food processing equipment.

Stick Welding in Heavy Fabrication

Shielded Metal Arc Welding (SMAW), or Stick, is known for its simplicity and ruggedness. It is often used outdoors for construction and pipeline repair because it can tolerate dirty or rusty metal and windy conditions better than gas-shielded processes.

Flux-Cored Welding for Structural Strength

Similar to MIG but using a tubular wire filled with flux, this method provides deep penetration and high deposition rates. It is essential for heavy structural steel erection and shipbuilding.

Resistance and Spot Welding in Mass Production

Used primarily in the automotive industry, spot welding joins overlapping metal sheets. Its ability to be automated makes it vital for the mass production of car bodies.

Importance of Welding Across Major Industries

The influence of welding extends into almost every sector of the global economy.

- Construction and Infrastructure: From the rebar inside concrete to the steel beams of bridges, welding provides the structural integrity required to support massive loads.

- Automotive and Transportation: Modern vehicles rely on welding for chassis strength and crash safety. High-strength steel welding protects passengers during impacts.

- Manufacturing and Industrial Equipment: The machines that make our consumer goods—presses, conveyors, and robotic arms—are themselves fabricated using welding.

- Energy, Oil, and Gas: This sector relies on welding for pipelines, offshore oil rigs, and wind turbine towers. These welds must withstand extreme pressures and harsh environments.

- Aerospace and Defense: Aircraft and military vehicles require materials that are both lightweight and incredibly strong. Precision welding allows for the use of advanced alloys that meet these strict criteria.

Precision and Quality Control: A Core Aspect of Welding Importance

The importance of welding is inextricably linked to precision. A weld that looks good on the surface might harbor internal defects like porosity, cracks, or lack of fusion. In high-stakes environments, these defects can lead to catastrophic failure.

This is why quality control is a massive part of the welding industry. Professional fabrication shops employ rigorous testing protocols. This ranges from simple visual inspection to non-destructive testing (NDT) methods like ultrasonic testing, radiography (X-ray), and magnetic particle inspection.

Certified welders and welding inspectors ensure that every joint meets the specific codes and standards required for the project. This dedication to precision ensures that the trust placed in welded structures is well-founded.

Importance of Skilled Welders in Metal Fabrication

Despite the rise of robotics, the human element remains vital. Skilled welders bring a level of expertise and adaptability that machines cannot yet replicate. A human welder can adjust their technique on the fly to account for slight variations in material fit-up or environmental conditions.

The importance of welding expertise is backed by rigorous certification processes. Welders must prove their ability to produce sound welds in various positions (flat, vertical, overhead) and on different materials. Their skill directly impacts the fabrication outcome. Poor workmanship leads to rework, project delays, and safety hazards. Investing in skilled labor is investing in the reliability of the final product.

Automation and Technology Reinforcing the Importance of Welding

Technology has not replaced the need for welding; it has enhanced it. Robotic welding systems have revolutionized mass production, offering unmatched consistency and speed. Automated welding cells can run 24/7, producing identical welds on thousands of parts, which drastically reduces the cost of goods.

Furthermore, advanced technologies like CNC (Computer Numerical Control) welding and laser-assisted welding allow for micro-welding in electronics and medical devices. These advancements reinforce the importance of welding by expanding its capabilities into microscopic applications that were previously impossible. Automation ensures reliability, reduces rework, and allows human welders to focus on complex, custom tasks that require critical thinking.

Importance of Welding in Custom and Specialized Fabrication

Not all fabrication involves mass-producing thousands of identical widgets. In the world of custom fabrication—whether it’s a bespoke architectural staircase, a prototype for a new machine, or a specialized tank for a chemical plant—welding is key.

Custom fabrication often involves complex geometries and exotic materials. Here, the collaboration between designers and welders is crucial. A skilled welder can advise on joint design to minimize distortion and maximize strength. The ability to weld dissimilar metals or handle difficult alloys allows fabricators to solve unique engineering challenges, proving that welding is as much an art as it is a science.

Safety Standards and Regulations Highlighting the Importance of Welding

The inherent risks of welding—high voltage, extreme heat, fumes, and UV radiation—necessitate strict safety standards. However, these regulations also highlight how important the process is. The existence of bodies like the American Welding Society (AWS) and OSHA regulations regarding welding safety serves to standardize quality.

Adherence to safety standards ensures that the welding environment is controlled and that the welders are protected. When a fabrication shop prioritizes safety compliance, it usually correlates with higher quality output. It demonstrates a level of professionalism and care that translates into the integrity of the welded products.

Environmental and Sustainability Benefits of Welding

Sustainability is a growing concern in manufacturing, and welding plays a positive role here. By enabling the repair and refurbishment of metal equipment, welding extends the lifecycle of machinery, keeping it out of landfills.

Furthermore, welding is generally more material-efficient than subtractive manufacturing processes (like machining away a block of metal). It adds material only where needed. Advances in energy-efficient power sources and inverter technology have also reduced the carbon footprint of the welding process itself. As industries move toward green energy, welding is essential for building the infrastructure of the future, such as solar panel arrays and hydrogen fuel cells.

Choosing the Right Welding Method: Why It Matters

Recognizing the importance of welding also means understanding that not all welds are created equal. Selecting the right method is a critical engineering decision. Factors influencing this choice include:

- Material Thickness: Heavy plate steel might require Flux-Cored welding, while thin aluminum sheet metal requires TIG.

- Production Scale: High-volume runs benefit from robotic MIG welding, while one-off repairs may be best suited for Stick welding.

- Location: Fieldwork often dictates the method based on portability and wind resistance.

Professional guidance is essential here. Using the wrong method can lead to weak joints, excessive costs, or product failure.

Why the Importance of Welding Makes Professional Fabrication Essential

Given the complexities discussed—from metallurgy and method selection to safety and inspection—the risks of relying on low-quality or amateur welding are high. While DIY welding is popular for hobbyists, structural and industrial applications demand professional fabrication.

Working with experienced fabricators ensures accountability. Professionals offer quality assurance, proper material certification, and the peace of mind that comes with knowing the structure will hold. In the long run, professional welding prevents costly repairs and liability issues, highlighting the economic and safety advantages of doing it right the first time.

Future Outlook: Why the Importance of Welding Will Continue to Grow

The future of welding is bright. As global infrastructure ages, the need for repair and retrofitting will surge, driving demand for skilled welders. Simultaneously, the rise of smart manufacturing and AI is making welding smarter. Sensors can now monitor weld parameters in real-time, adjusting the arc to prevent defects before they happen.

New materials, such as advanced high-strength steels and lightweight aluminum-lithium alloys used in space travel, will require new welding techniques. As we look toward a future of renewable energy and interplanetary exploration, welding will remain the essential process that builds the path forward.

The Lasting Importance of Welding in Industry

From the cars we drive to the energy we consume, our world is built on welded joints. The welding in modern metal fabrication cannot be overstated. It provides the strength, versatility, and efficiency required to turn raw metal into the functional reality of our modern world.

As a discipline that combines chemistry, physics, and manual dexterity, welding remains the backbone of metal fabrication. For businesses and industries looking to build for the future, understanding and investing in high-quality welding solutions is not just an option—it is a necessity. If you are planning a project where failure is not an option, ensure you have the right welding expertise on your side.