When standard parts fail to meet the unique demands of a project, custom metal fabrication provides the solution. It is the bridge between a digital design and a tangible, high-performance product. Whether you are building complex industrial machinery or architectural structures, the quality of the fabrication determines the success of the final outcome.

Custom metal fabrication is not just about cutting and bending steel; it is a comprehensive manufacturing process that transforms raw materials into specialized components. Unlike mass-produced parts, custom fabrication caters to specific project requirements, ensuring that every bracket, frame, and enclosure fits perfectly and performs reliably.

This guide explores the essential services involved in custom metal fabrication, the materials used, and why partnering with a professional fabrication team is critical for modern industry.

What is custom metal fabrication?

Custom metal fabrication is the process of cutting, shaping, and assembling metal structures based on specific design specifications.

It involves taking raw stock—such as sheet metal, tubes, or bars—and manipulating it through various industrial techniques to create a final part. While standard fabrication produces generic components in bulk, custom fabrication focuses on the unique needs of a specific application. This approach relies heavily on engineering expertise and precision manufacturing. A fabricator must understand how different metals react to heat and stress, ensuring the final product maintains its structural integrity.

Why is custom metal fabrication important?

Custom fabrication is essential because it delivers precision, durability, and efficiency that off-the-shelf parts cannot match.

Precision and Accuracy

In industries like aerospace and automotive, a fraction of a millimeter can be the difference between success and failure. Custom fabrication allows for tight tolerances, ensuring components fit seamlessly into larger assemblies.

Improved Performance

Parts designed specifically for an application perform better. They can be reinforced where stress is highest and lightened where weight is a concern, optimizing the overall function of the machine or structure.

Cost Efficiency

While custom parts may have a higher upfront cost than mass-produced items, they often save money in the long run. They reduce the need for modifications during assembly and last longer due to superior build quality, lowering maintenance and replacement costs.

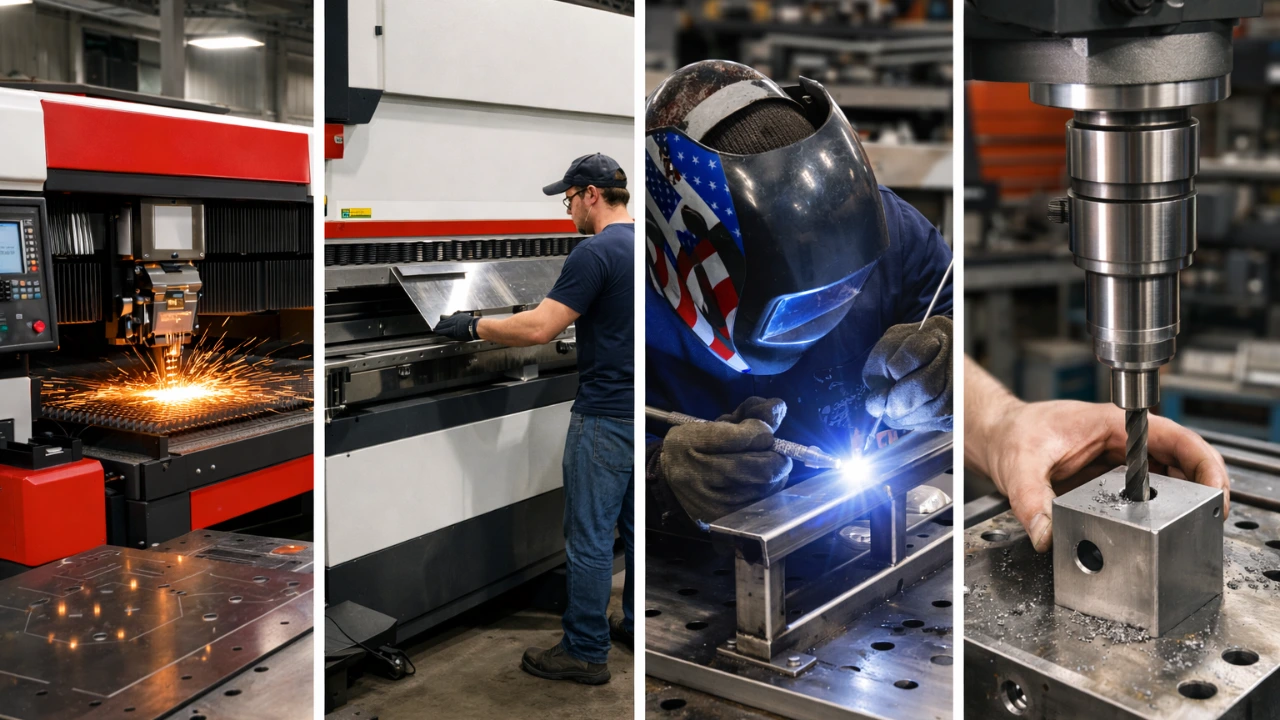

Types of Custom Metal Fabrication Services We Provide

We offer a comprehensive suite of fabrication services designed to handle projects from prototype to full-scale production.

Laser Cutting Services

Laser cutting uses a high-powered laser beam to slice through metal with extreme accuracy. This contactless process prevents material distortion and leaves a clean edge that requires minimal finishing.

- Flat Laser Cutting: Ideal for sheet metal, creating intricate shapes and holes with high speed and precision.

- Tube Laser Cutting: Used for processing structural shapes like pipes and square tubing, allowing for complex slotting and coping that traditional saws cannot achieve.

CNC Bending & Press Brake Forming

Computer Numerical Control (CNC) bending turns flat sheet metal into three-dimensional parts. Our press brakes apply tons of force to bend metal at precise angles. This allows us to create complex shapes, channels, and enclosures with consistent accuracy across large production runs.

Metal Tapping & Threading

To ensure parts are ready for assembly, we provide internal threading solutions.

- Manual Tapping: For low-volume or delicate work.

- CNC Tapping: Automated threading integrated into the machining process for speed and consistency.

Welding & Assembly

Welding is the core of structural fabrication. We employ certified welders and advanced technology to join metal components securely.

- MIG Welding: Great for thicker sections and structural steel.

- TIG Welding: Provides precise, high-quality welds for thinner materials like stainless steel and aluminum.

- Robotic Welding: Used for high-volume projects requiring identical, repetitive welds.

Bead Blasting & Surface Finishing

The fabrication process isn’t complete until the surface is treated. Bead blasting involves shooting abrasive beads at the metal surface under high pressure. This removes manufacturing marks, cleans the metal, and provides a uniform matte finish. It also prepares the surface for better adhesion if powder coating or painting is required later.

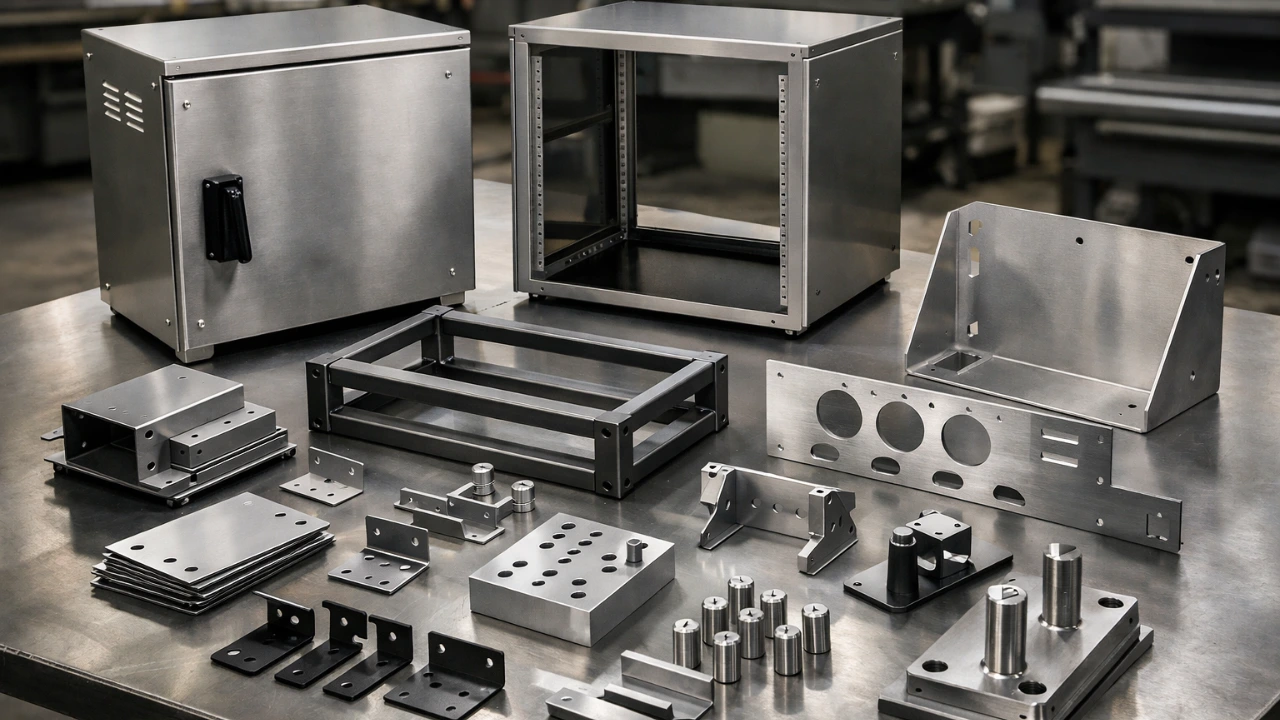

Custom Sheet Metal Fabrication

We specialize in turning flat sheets into functional products. This includes fabricating:

- Electrical enclosures

- Mounting brackets

- Control panels

- Machine frames

- Architectural features

Materials We Work With

Choosing the right material is just as important as the fabrication method. We work with a wide range of metals to suit different environmental and structural needs.

- Mild Steel: The most common choice for structural applications due to its high strength, weldability, and cost-effectiveness.

- Stainless Steel: Known for its corrosion resistance and hygiene properties, making it ideal for food processing, medical, and outdoor applications.

- Aluminum: Lightweight yet strong, aluminum is widely used in aerospace and transportation where weight reduction is a priority.

- Brass and Copper: Often chosen for their electrical conductivity or aesthetic appeal in architectural projects.

- Special Alloys: We can source and fabricate exotic alloys for environments requiring extreme heat or chemical resistance.

Industries That Use Custom Metal Fabrication

Our services support a diverse range of sectors, each with its own rigorous standards.

- Automotive and Transportation: From chassis components to custom brackets for vehicle modifications.

- Industrial Machinery: Frames, guards, and internal components for manufacturing equipment.

- Construction and Architecture: Structural beams, decorative facades, and custom railings.

- Aerospace and Defense: High-precision parts that require strict adherence to quality and safety regulations.

- Energy: Components for renewable energy systems, including solar frames and wind turbine parts.

Why Choose Us for Custom Metal Fabrication

Selecting a fabrication partner is an investment in your project’s reliability.

Skilled Team

Our team consists of experienced engineers, machinists, and certified welders who understand the nuances of metalworking. We solve problems before they reach the production floor.

Advanced Machinery

We invest in the latest CNC technology. Automated machinery ensures that the thousandth part we produce is exactly the same as the first.

Strict Quality Control

Quality is not an afterthought. We employ rigorous inspection protocols at every stage of fabrication, ensuring that every dimension meets your specified tolerances.

Reliable Turnaround

We understand that production delays cost money. Our efficient workflow allows us to meet deadlines without compromising on quality.

Our Custom Metal Fabrication Process

We follow a structured workflow to ensure transparency and efficiency.

- Design Review: We analyze your CAD drawings and provide engineering feedback to improve manufacturability and reduce costs.

- Material Selection: We help you choose the best metal for the application and source it from trusted suppliers.

- Precision Cutting & Forming: Materials are processed using our laser cutters and press brakes.

- Welding & Assembly: Components are joined and assembled into the final structure.

- Finishing: Parts are bead blasted, tapped, or coated as required.

- Final Inspection: A comprehensive quality check is performed before shipping.

Benefits of Working With a Professional Custom Metal Fabrication Company

Partnering with a professional shop removes the guesswork from manufacturing.

- Reduced Risk: Experts identify design flaws early, preventing costly rework.

- Consistent Quality: Professional shops have ISO-standard processes that guarantee uniformity.

- Scalability: Whether you need a single prototype or a run of 10,000 units, a professional fabricator has the capacity to scale with your growth.

- One-Stop Solution: From cutting to finishing, handling everything under one roof streamlines logistics and communication.

The Right Partner for Precision Results

Custom metal fabrication is the backbone of modern innovation. It allows engineers and designers to push boundaries, knowing that their specific requirements can be met with exact precision. By utilizing advanced services like laser cutting, CNC bending, and robotic welding, industries can build safer, more efficient, and more durable products.

Choosing the right fabrication partner ensures that your designs are executed flawlessly. It transforms raw metal into a competitive advantage for your business.

Ready to Start Your Custom Metal Fabrication Project?

If you need reliable, high-precision custom metal fabrication services, Toledofab is here to help. Connect with us today to discuss your requirements, get expert guidance, and receive a tailored solution for your project.