Flat laser cutting has become one of the most important technologies in modern metal fabrication. As industries continue to demand higher accuracy, faster production, and better material efficiency, flat laser cutting stands out as a reliable and advanced solution. From simple sheet metal parts to complex industrial components, this technology enables manufacturers to achieve clean cuts, tight tolerances, and consistent quality at scale.

In today’s competitive manufacturing environment, precision and efficiency are not optional. Flat laser cutting meets these demands by combining advanced laser technology with automated controls, making it an essential process across multiple industries.

This comprehensive guide explains what flat laser cutting is, how it works, its benefits, applications, materials, and why it is the preferred choice for modern fabrication needs.

What Is Flat Laser Cutting

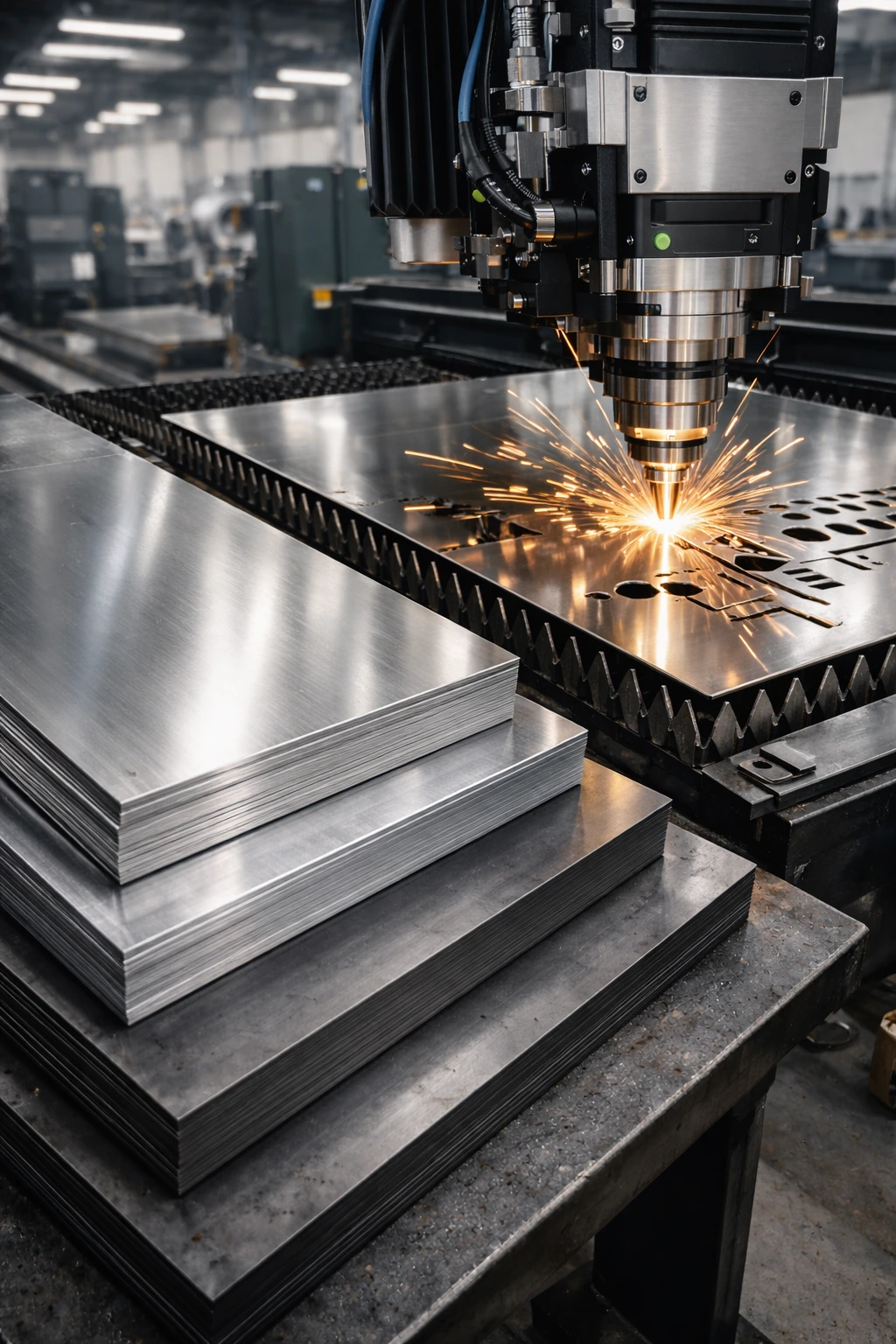

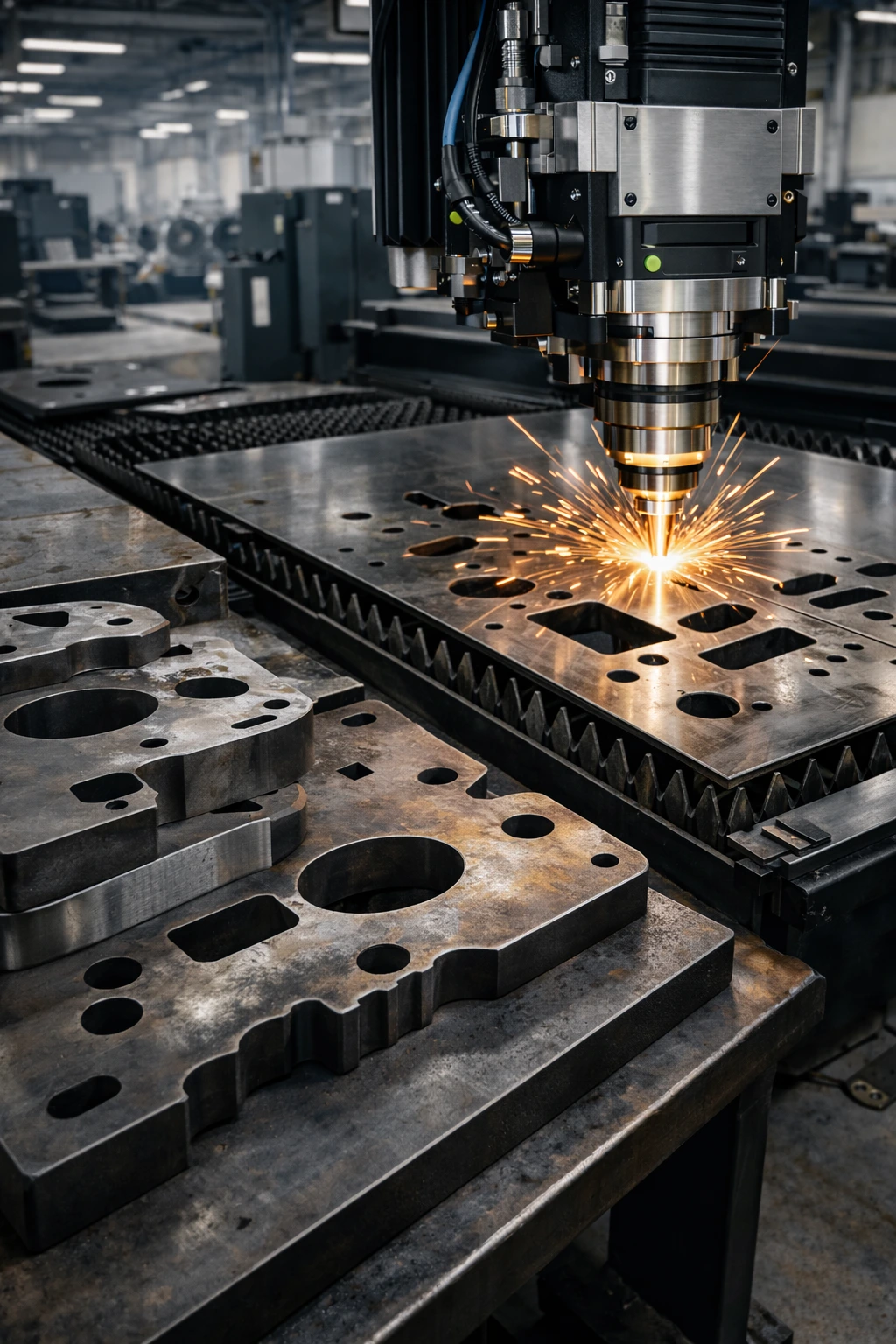

Flat laser cutting is a manufacturing process that uses a high powered laser beam to cut flat sheet materials with exceptional precision. The laser focuses intense heat on a specific point, melting or vaporizing the material to create accurate and smooth cuts. Computer controlled systems guide the laser based on digital design files, ensuring repeatable and precise results.

This process is commonly used for cutting sheet metals such as stainless steel, aluminum, mild steel, and carbon steel. Unlike traditional cutting methods, flat laser cutting does not rely on physical contact, which reduces tool wear and improves consistency.

Because of its flexibility and accuracy, flat laser cutting is widely used for both prototype development and high volume production.

How Flat Laser Cutting Works

The flat laser cutting process begins with a digital design, usually created using CAD software. This design file is uploaded to the laser cutting machine, which follows the programmed path with extreme precision.

A powerful laser beam is generated and focused through a cutting head onto the flat metal sheet. The heat from the laser melts, burns, or vaporizes the material at the cutting point. Assist gases such as oxygen or nitrogen are often used to remove molten material and improve cut quality.

The entire process is automated, which allows for consistent cuts, minimal errors, and high production speed.

Key Benefits of Flat Laser Cutting

Flat laser cutting offers several advantages that make it superior to traditional cutting methods.

Exceptional Precision

One of the biggest benefits of flat laser cutting is its ability to produce extremely accurate cuts. Tight tolerances and complex geometries can be achieved with ease, making it ideal for detailed designs and precision components.

High Production Speed

Laser cutting machines operate at high speeds, significantly reducing production time. This allows manufacturers to meet tight deadlines without compromising quality.

Clean and Smooth Edges

Flat laser cutting produces smooth, burr free edges that often eliminate the need for secondary finishing processes. This improves efficiency and reduces overall production costs.

Reduced Material Waste

The precision of flat laser cutting allows for optimized nesting of parts, which minimizes material waste. This is especially important when working with expensive metals.

Consistent and Repeatable Results

Because the process is computer controlled, each cut is identical to the last. This ensures consistent quality across large production runs.

Versatility in Design

Flat laser cutting can handle intricate patterns, sharp corners, and detailed cutouts that are difficult or impossible with conventional methods.

Materials Commonly Used in Flat Laser Cutting

Flat laser cutting is compatible with a wide range of materials, making it a versatile solution for different industries.

Stainless Steel

Stainless steel is one of the most commonly cut materials using flat laser technology. The process delivers clean edges and precise cuts without distorting the material.

Aluminum

Laser cutting aluminum requires precision due to its reflective nature. Modern flat laser machines are designed to handle aluminum efficiently, producing accurate results.

Mild Steel and Carbon Steel

Flat laser cutting is highly effective for mild steel and carbon steel sheets, offering fast cutting speeds and excellent edge quality.

Brass and Copper

With the right laser configuration, flat laser cutting can also be used for brass and copper, enabling detailed designs and clean finishes.

Applications of Flat Laser Cutting Across Industries

Flat laser cutting is used in a wide range of industries due to its adaptability and precision.

Automotive Industry

In the automotive sector, flat laser cutting is used to manufacture brackets, panels, frames, and structural components. The accuracy of the process ensures that parts fit perfectly during assembly.

Construction and Architecture

Architectural projects often require custom metal components and decorative panels. Flat laser cutting allows for intricate designs and precise structural elements that enhance both functionality and aesthetics.

Industrial Manufacturing

Industrial fabrication relies heavily on flat laser cutting for producing machine parts, enclosures, frames, and support structures. The consistency of laser cutting ensures reliable performance in demanding environments.

Electronics and Electrical Industry

Flat laser cutting is ideal for thin metal sheets and delicate components used in electronics. The process minimizes heat distortion, protecting sensitive designs.

Furniture and Interior Design

Modern furniture and interior designs often feature custom metal patterns and decorative elements. Flat laser cutting enables designers to bring creative concepts to life with precision.

Flat Laser Cutting vs Traditional Cutting Methods

Compared to traditional cutting techniques such as punching, sawing, and plasma cutting, flat laser cutting offers several advantages.

Traditional methods often involve mechanical force, which can lead to material deformation, rough edges, and limited design flexibility. Plasma cutting, while fast, typically produces wider kerfs and less precise edges.

Flat laser cutting, on the other hand, delivers superior accuracy, cleaner cuts, and reduced heat affected zones. It also eliminates the need for frequent tool changes, making it more efficient for complex projects.

The Role of Automation in Flat Laser Cutting

Automation plays a significant role in modern flat laser cutting systems. Automated loading and unloading, real time monitoring, and intelligent software integration improve productivity and reduce human error.

Advanced machines can automatically adjust cutting parameters based on material type and thickness. This ensures optimal performance and consistent results across different projects.

Automation also allows manufacturers to scale production while maintaining high quality standards.

Cost Efficiency of Flat Laser Cutting

While the initial investment in laser cutting technology may be higher than traditional equipment, the long term cost benefits are significant.

Flat laser cutting reduces material waste, minimizes secondary operations, and lowers labor costs through automation. Faster production speeds also mean shorter lead times and increased output.

For businesses focused on efficiency and profitability, flat laser cutting offers excellent value.

Quality Control and Accuracy

Quality control is critical in metal fabrication, and flat laser cutting excels in this area. The precision of the laser and the accuracy of computer controlled systems ensure that every part meets design specifications.

This level of control is especially important for industries that require strict tolerances and consistent performance.

Environmental Benefits of Flat Laser Cutting

Flat laser cutting is also considered an environmentally friendly manufacturing process. Reduced material waste, efficient energy usage, and minimal need for secondary processing contribute to a lower environmental impact.

Optimized cutting paths and efficient use of raw materials make flat laser cutting a sustainable choice for modern manufacturing.

Choosing the Right Flat Laser Cutting Partner

Selecting the right fabrication partner is essential to achieving the best results. A reliable provider will have modern equipment, experienced operators, and a strong focus on quality control.

Look for a company that offers design support, material expertise, and flexible production capabilities. This ensures that your project is completed efficiently and meets all requirements.

Why Flat Laser Cutting Is the Future of Sheet Metal Fabrication

As technology continues to evolve, flat laser cutting remains at the forefront of sheet metal fabrication. Its ability to deliver precision, speed, and consistency makes it ideal for both small scale projects and large volume production.

Manufacturers across industries are increasingly adopting flat laser cutting to stay competitive and meet growing market demands.

Conclusion

laser cutting has transformed the way metal components are manufactured. By combining advanced laser technology with automation and digital design, it delivers unmatched precision, efficiency, and versatility.

Whether you need custom prototypes, intricate designs, or high volume production, Toledo Fab’s flat laser cutting provides reliable and high quality results. Its wide range of applications, material compatibility, and cost effectiveness make it an essential process in modern fabrication.

For businesses looking to improve quality, reduce waste, and increase productivity, flat laser cutting is the smart and future ready solution.