Metal fabrication plays a critical role in modern manufacturing, construction, and industrial development. From structural components to custom parts, the quality of fabrication directly affects strength, performance, and long term reliability. Understanding the metal fabrication process helps businesses choose the right partner and ensures projects are completed efficiently and accurately.

At Toledo Fab, metal fabrication is more than cutting and welding metal. It is a carefully managed process that combines engineering expertise, advanced machinery, skilled craftsmanship, and strict quality control. Every project is handled with attention to detail from the initial concept to final delivery.

In this guide, we walk you through the complete metal fabrication process followed at Toledo Fab and explain how precision, quality, and experience come together to deliver dependable results for our clients.

What Is the Metal Fabrication Process

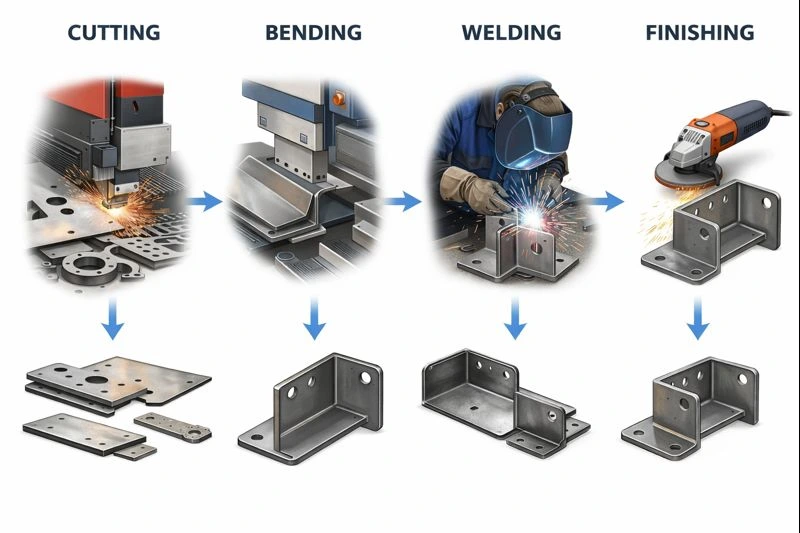

The metal fabrication process refers to the method of transforming raw metal materials into finished products or components. This involves cutting, shaping, forming, welding, assembling, and finishing metal based on specific project requirements.

Metal fabrication is used across a wide range of industries including manufacturing, construction, automotive, agriculture, and energy. Whether it is a small custom bracket or a large structural assembly, the process must be accurate and consistent to meet performance and safety standards.

There are two main types of fabrication. Standard fabrication involves producing commonly used components with fixed specifications. Custom metal fabrication focuses on unique designs tailored to specific applications. Toledo Fab specializes in custom metal fabrication, delivering solutions that meet exact client needs.

A reliable metal fabrication process ensures dimensional accuracy, material integrity, and long term durability. Every stage must be carefully planned and executed to avoid errors, delays, and unnecessary costs.

Step by Step Metal Fabrication Process We Follow at Toledo Fab

At Toledo Fab, our fabrication process is designed to deliver precision, efficiency, and repeatable quality. Each step builds upon the previous one to ensure the final product meets or exceeds expectations.

Project Consultation and Requirement Analysis

Every successful fabrication project begins with a clear understanding of requirements. During the consultation stage, we work closely with clients to gather detailed information about their project.

This includes reviewing drawings, specifications, tolerances, quantities, and application requirements. We discuss performance expectations, environmental conditions, and any industry standards that must be met.

Our team also provides guidance on material selection, fabrication methods, and design feasibility. This early collaboration helps prevent costly changes later in the process and ensures the project is aligned with both functional and budget goals.

Clear communication at this stage allows us to create a solid foundation for the entire metal fabrication process.

Engineering, Design, and CAD Modeling

Once requirements are finalized, the project moves into the engineering and design phase. Modern metal fabrication relies heavily on digital tools to ensure accuracy and efficiency.

Using advanced CAD and CAM software, our engineers create detailed models and fabrication drawings. These designs allow us to visualize the final product, verify dimensions, and identify potential issues before production begins.

Design optimization is a key part of this step. We evaluate strength, material usage, manufacturability, and cost efficiency. In some cases, prototypes or test components are created to validate the design.

Client approval is obtained before moving forward, ensuring complete confidence in the fabrication plan.

Material Selection and Preparation

Choosing the right material is essential to the success of any metal fabrication project. At Toledo Fab, we work with a wide range of metals including carbon steel, stainless steel, and aluminum.

Material selection depends on factors such as load requirements, corrosion resistance, weight, and operating environment. Thickness, grade, and finish are carefully considered to match the intended application.

Once materials are sourced, they are inspected for quality and consistency. Proper storage and preparation ensure the material is ready for precise cutting and forming. This step reduces waste and improves overall efficiency throughout the fabrication process.

Metal Cutting Techniques

Cutting is one of the most critical stages of the metal fabrication process. Precision cutting ensures parts fit together correctly and meet design tolerances.

Toledo Fab uses a variety of cutting methods depending on the material and project requirements. CNC laser cutting provides exceptional accuracy for complex shapes and thin materials. Plasma cutting is effective for thicker metals and heavy duty applications. Waterjet cutting allows for clean cuts without heat distortion, making it ideal for sensitive materials.

Sawing and shearing are also used for straightforward cuts and high volume production. Each cutting method is selected based on accuracy, efficiency, and cost effectiveness.

Advanced CNC equipment ensures repeatable results and minimal material waste.

Metal Forming and Shaping

After cutting, metal components are shaped to achieve the required geometry. Forming and shaping processes include bending, rolling, stamping, and press brake operations.

Bending is used to create angles and folds while maintaining material strength. Rolling forms curved components such as cylinders or arcs. Stamping is ideal for producing consistent shapes in larger quantities.

Precision is essential during forming to maintain dimensional accuracy and structural integrity. Our skilled operators carefully control pressure and angles to ensure each component meets specifications.

This stage transforms flat metal into functional parts ready for assembly.

Welding and Assembly

Welding and assembly bring individual components together to create the final structure. This stage requires skilled craftsmanship and attention to detail.

Toledo Fab offers MIG welding, TIG welding, and structural welding based on material type and application. Each welding method is chosen to provide strength, durability, and clean finishes.

During assembly, components are aligned and fitted to ensure proper connections and load distribution. Fixtures and jigs are often used to maintain consistency and accuracy.

Strong welds and precise assembly are essential for safety, performance, and longevity in fabricated metal products.

Surface Finishing and Treatments

Surface finishing enhances both the appearance and performance of fabricated metal. It also protects components from corrosion, wear, and environmental damage.

Common finishing processes include grinding, polishing, painting, powder coating, and galvanizing. Grinding and polishing remove imperfections and create smooth surfaces. Powder coating and painting improve aesthetics while adding a protective layer. Galvanizing provides long term corrosion resistance for outdoor and industrial applications.

The choice of finish depends on the environment in which the product will be used and the desired appearance. Proper finishing extends the life of fabricated metal components.

Quality Control and Inspection

Quality control is integrated throughout the entire metal fabrication process at Toledo Fab. Final inspection ensures that every component meets design specifications and industry standards.

This includes dimensional checks, weld inspections, and visual evaluations. Measurements are verified using precision tools to confirm accuracy and consistency.

Any issues identified during inspection are addressed before delivery. This commitment to quality ensures reliable performance and reduces the risk of failures in the field.

Packaging, Delivery, and Installation Support

Once fabrication and inspection are complete, products are carefully packaged to prevent damage during transportation. Secure packaging protects finished surfaces and structural integrity.

We coordinate delivery schedules to meet project timelines and minimize downtime. When required, installation support and coordination are also provided to ensure proper placement and functionality.

Timely delivery and dependable logistics complete the metal fabrication process and ensure a smooth experience for our clients.

Why Precision Matters in the Metal Fabrication Process

Precision is the foundation of successful metal fabrication. Even small errors can lead to misalignment, reduced strength, or operational failures.

Accurate fabrication ensures components fit correctly, perform as intended, and meet safety requirements. Precision also reduces material waste, rework, and project delays.

For industries such as manufacturing and construction, precision fabrication contributes to long term reliability and cost savings. At Toledo Fab, every stage of the process is designed to maintain tight tolerances and consistent quality.

Industries We Serve With Our Metal Fabrication Process

Our metal fabrication services support a wide range of industries with diverse requirements.

Manufacturing operations rely on fabricated components for machinery, equipment frames, and production systems. Construction projects require structural steel, supports, and custom assemblies. Automotive and transportation industries depend on precision fabricated parts for performance and safety.

Agricultural equipment, energy infrastructure, and industrial facilities also benefit from durable and custom fabricated metal solutions. Our experience across multiple industries allows us to adapt our process to meet specific application demands.

Benefits of Choosing Toledo Fab for Your Metal Fabrication Needs

Choosing the right fabrication partner can make a significant difference in project success. Toledo Fab offers experience, technology, and dedication to quality.

Our skilled team understands complex fabrication requirements and delivers custom solutions. Advanced machinery ensures accuracy and efficiency. Quality control processes maintain consistent results.

As a trusted metal fabrication provider in Ohio, we prioritize communication, reliability, and customer satisfaction. Each project is handled with care and professionalism from start to finish.

Common Challenges in Metal Fabrication and How We Solve Them

Metal fabrication can present challenges such as tight deadlines, complex designs, and material constraints. Without proper planning, these challenges can lead to delays and increased costs.

At Toledo Fab, we address these challenges through early collaboration, detailed planning, and advanced technology. Design optimization reduces complexity. Efficient workflows improve turnaround times. Skilled craftsmanship ensures quality even on demanding projects.

Our proactive approach helps prevent issues and keeps projects on track.

How to Choose the Right Metal Fabrication Partner

Selecting a fabrication partner requires careful consideration. Experience, equipment, and quality standards are essential factors.

Look for a company with proven expertise, modern machinery, and a commitment to quality. Clear communication and transparency are also important for smooth project execution.

A reliable metal fabrication partner acts as an extension of your team, providing guidance and solutions throughout the process. Toledo Fab is dedicated to building long term partnerships based on trust and performance.

Frequently Asked Questions About the Metal Fabrication Process

Many clients have questions about fabrication timelines and materials. Project duration depends on complexity, quantity, and finishing requirements. Simple projects may take days, while complex assemblies require more time.

Steel, aluminum, and stainless steel are commonly used metals. The best choice depends on strength, weight, and environmental exposure.

Welding is one part of fabrication, while fabrication includes cutting, forming, assembling, and finishing. Toledo Fab handles both custom and large scale fabrication projects.

Conclusion

The metal fabrication process is a combination of engineering, craftsmanship, and precision. Each step plays a vital role in creating durable and reliable metal products.

At Toledo Fab, we follow a structured and proven fabrication process that delivers consistent quality from concept to completion. Our commitment to precision, safety, and customer satisfaction ensures that every project meets the highest standards.

If you are looking for a dependable metal fabrication partner, Toledo Fab is ready to support your next project. Contact us today to discuss your requirements and discover how our expertise can bring your ideas to life.