Choosing the right metal for your project—whether it’s a new watch, a 4×4 upgrade, or industrial machinery—can feel like navigating a maze of technical jargon. You’ll often hear two contenders mentioned more than any others: titanium and stainless steel. Both are celebrated for their strength and durability, yet they serve very different purposes depending on the application.

Titanium vs stainless steel is a debate that touches on cost, weight, and long-term performance. While stainless steel is the go-to for affordable durability and shiny aesthetics, titanium is often the choice for those needing lightweight performance and superior corrosion resistance. Understanding the nuances between these two materials will ensure you pick the right metal for durability, cost, and weight, avoiding expensive mistakes down the line.

Understanding the Metals

Before diving into a direct comparison, it’s helpful to understand exactly what we are working with. Both metals are alloys, meaning they are mixtures of elements designed to enhance specific properties like strength or rust resistance.

What is Titanium?

Titanium is a transition metal known for being as strong as steel but significantly lighter. It has a high tensile strength and is naturally resistant to corrosion, thanks to a thin oxide film that forms on its surface when exposed to air.

There are various grades of titanium, generally categorized into commercially pure grades (Grades 1–4) and alloys (like Grade 5, often used in aerospace).

- Grade 1–4: Excellent corrosion resistance, easier to form.

- Grade 5 (Ti-6Al-4V): The most common alloy, offering extremely high strength and heat resistance.

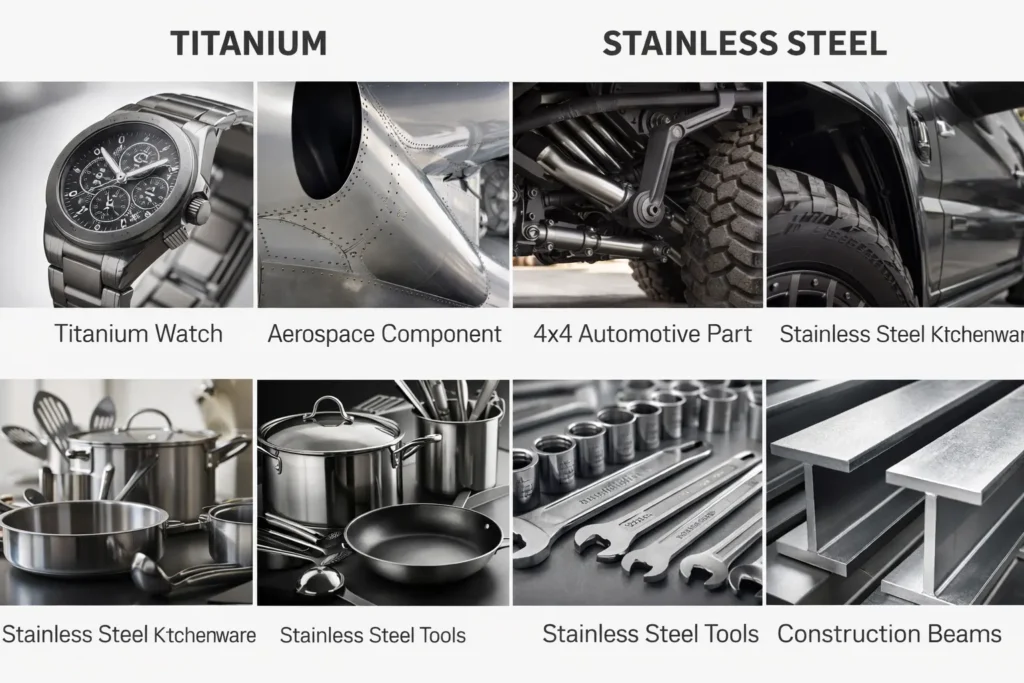

Common applications include aerospace components, medical implants (because it’s biocompatible), high-performance automotive parts, and premium jewelry. Its lifespan is exceptional; titanium structures can last decades without significant degradation, even in harsh saltwater environments.

What is Stainless Steel?

Stainless steel is an alloy of iron, carbon, and chromium. The chromium is the secret ingredient that prevents rust. It is durable, widely available, and generally heavier than titanium.

Like titanium, stainless steel comes in different families and grades:

- 304 Stainless Steel: The standard “18/8” stainless used in kitchenware and appliances.

- 316 Stainless Steel: Contains molybdenum for better resistance to salt and chlorides (marine grade).

- 430 Stainless Steel: Magnetic and less corrosion-resistant, often used for decorative trim.

You’ll find stainless steel everywhere—from the cutlery in your drawer to the structural beams of skyscrapers and the exhaust systems of cars.

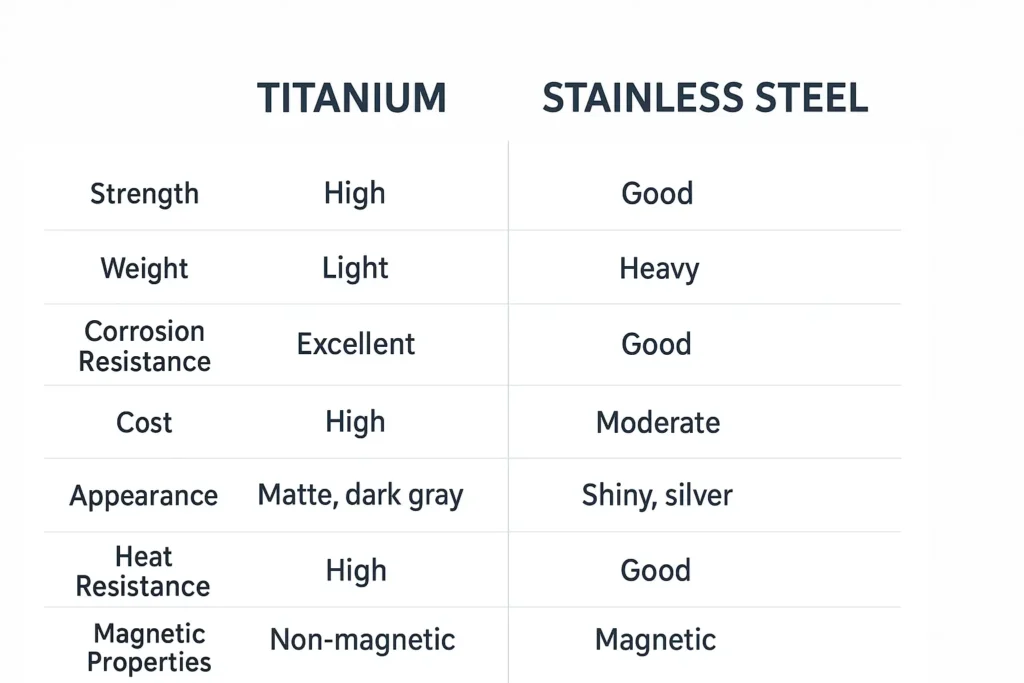

Titanium Steel vs Stainless Steel

You might see the term “titanium steel” used in marketing, particularly for jewelry. It’s often a misnomer or a marketing term for stainless steel that has been coated or treated to look like titanium or has a very small amount of titanium added. However, regarding the raw material properties, here is a quick look at what is titanium steel vs stainless steel (treating titanium steel as pure titanium for this comparison):

Property | Titanium | Stainless Steel |

|---|---|---|

Base Element | Titanium (Ti) | Iron (Fe) |

Density | Low (~4.5 g/cm³) | High (~8.0 g/cm³) |

Strength-to-Weight | High | Moderate |

Cost | High | Low to Moderate |

Key Differences Between Titanium and Stainless Steel

To determine which metal wins the titanium vs stainless steel battle, we need to break down their specific characteristics.

Strength and Durability

If you are looking at raw strength, steel alloys can technically be made stronger than pure titanium. However, the magic of titanium lies in its strength-to-weight ratio. Titanium is roughly as strong as steel but is about 45% lighter. This means for the same weight, titanium is much stronger.

Stainless steel is incredibly durable and resistant to impact. It is less likely to crack under brittle fracture conditions compared to some titanium alloys, but it is prone to fatigue over very long periods compared to the superior fatigue resistance of titanium.

Weight and Density

This is often the deciding factor. Titanium is approximately 40–45% lighter than stainless steel.

- Aerospace: Every gram counts, making titanium essential.

- Jewelry: A bulky stainless steel watch feels heavy on the wrist; a titanium watch of the same size feels almost weightless.

- Vehicles: Reducing unsprung weight in cars (like lug nuts or suspension parts) improves handling, favoring titanium.

Corrosion and Chemical Resistance

Titanium is the clear winner here. It is virtually immune to atmospheric corrosion and resists rust, oxidation, and acids exceptionally well. You can leave a piece of titanium in seawater for years, and it will look the same as the day you dropped it.

Stainless steel resists rust well—hence the name—but it is not stain-proof. In high-salinity environments or when exposed to chlorides (like swimming pools), standard 304 stainless steel can pit and rust. You need to upgrade to 316 grade for better protection, but even then, it can’t match titanium’s natural immunity.

Cost Comparison

Titanium is expensive. The extraction process (Kroll process) is labor-intensive and energy-hungry, and machining the metal wears out tools quickly. This drives up the price of the final product.

Stainless steel is budget-friendly. It is easier to produce and manufacture, making it the practical choice for large-scale construction and everyday consumer goods where extreme weight savings aren’t critical.

Appearance and Finish

- Titanium: Generally has a darker, matte gray metallic look. It looks more industrial and understated. Interestingly, titanium can be anodized to create brilliant colors (blues, purples, golds) without using dyes, simply by altering the thickness of the surface oxide layer.

- Stainless Steel: Typically brighter, shinier, and more silver. It can be polished to a mirror finish, which is why it is preferred for decorative items, kitchen appliances, and classic jewelry.

Thermal Conductivity and Heat Resistance

Titanium has low thermal conductivity. It doesn’t transfer heat quickly, which makes it comfortable to wear (it doesn’t feel freezing cold in winter or scalding hot in summer). It also maintains its strength at high temperatures.

Stainless steel has higher thermal conductivity compared to titanium (though lower than aluminum). However, it can warp or lose strength if exposed to extreme heat for prolonged periods, whereas titanium is often used in jet engines for this very reason.

Magnetic Properties

- Titanium: Non-magnetic. This is crucial for medical implants (safe for MRIs) and high-end watches (mechanisms won’t be disrupted by magnetic fields).

- Stainless Steel: It depends. Austenitic steels (like 304 and 316) are generally non-magnetic, but can become slightly magnetic when worked. Ferritic and martensitic steels (like 400 series) are magnetic.

How to Tell Titanium vs Stainless Steel

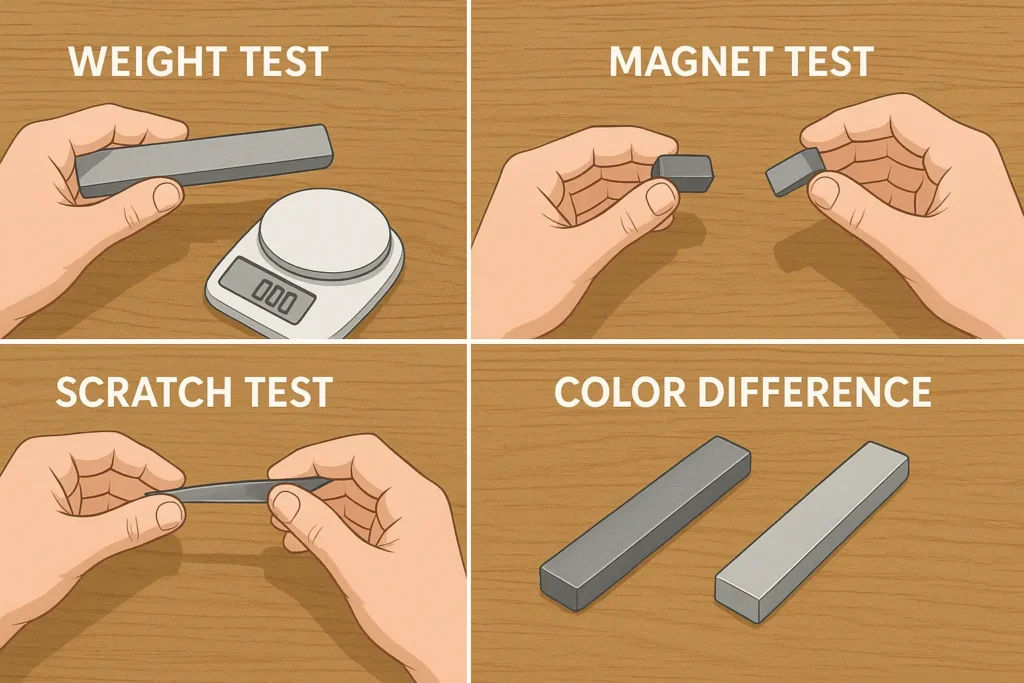

If you have two pieces of metal and aren’t sure which is which, here is how to tell titanium vs stainless steel using a few simple tests.

Visual Inspection

Look at the color. Stainless steel usually has a brighter, whiter, silver shine. Titanium tends to be a darker, muted gray, somewhat similar to gunmetal. If the metal is anodized in a bright rainbow color, it’s likely titanium.

Weight Test

Hold the items in your hand. If they are roughly the same size, the titanium piece will feel surprisingly light, almost like aluminum but harder. The stainless steel piece will feel dense and substantial.

Magnet Test

Use a strong magnet. If the magnet sticks firmly, it is almost certainly a grade of stainless steel (or regular steel). If it doesn’t stick at all, it could be titanium or high-grade stainless (304/316). While not definitive on its own, it helps rule out magnetic steel grades.

Scratch and Hardness Test

Titanium is generally harder and more scratch-resistant than stainless steel, although it can still scratch. If you run a file across an inconspicuous area:

- Titanium: Will produce white sparks (if using a grinder) and is very resistant to filing.

- Stainless Steel: Will produce orange/yellow sparks and files down more easily.

Chemical or Acid Test

This is more extreme, but titanium is unaffected by most acids. Stainless steel can discolor or corrode if exposed to strong hydrochloric or sulfuric acid. (Always exercise caution with chemicals).

Applications: When to Use Titanium vs Stainless Steel

Choosing between these metals depends entirely on what you need the object to do.

Jewelry and Watches

Titanium is hypoallergenic, meaning it won’t cause skin irritation for those with nickel allergies (a common issue with some stainless steel). It is lightweight and comfortable for all-day wear. Stainless steel is preferred for “dressy” watches due to its high polish and weighty, premium feel.

Medical Implants and Surgical Tools

Titanium is the gold standard for implants (hips, knees, dental posts) because it is biocompatible—the bone can actually grow into the metal (osseointegration). Stainless steel is still widely used for surgical tools (scalpels, clamps) because it is durable, easy to sterilize, and sharpens well.

Industrial and Automotive Parts

For high-performance automotive and 4×4 parts, titanium is used for exhausts, valves, and suspension springs to reduce weight. However, due to cost, stainless steel is the standard for exhaust systems and structural components in 99% of vehicles.

Consumer Products

- Titanium: Camping gear (super light mugs/pots), high-end spectacle frames, premium EDC (everyday carry) pens.

- Stainless Steel: Kitchen sinks, cutlery, washing machine drums, screwdrivers, wrenches.

Pros and Cons of Titanium and Stainless Steel

Here is a quick reference table to help summarize the trade-offs.

Feature | Titanium | Stainless Steel |

|---|---|---|

Strength | High (High Strength-to-Weight) | Medium to High |

Weight | Light | Heavy |

Corrosion | Excellent (Saltwater proof) | Good (Can pit in harsh conditions) |

Cost | High | Affordable |

Appearance | Matte, darker gray | Shiny, silvery, reflective |

Heat Resistance | Excellent | Moderate |

Magnetic | Non-magnetic | Sometimes magnetic |

Titanium vs Stainless Steel: Cost vs Value

When analyzing does stainless steel vs titanium offer better value, you have to look at longevity vs. upfront cost.

Titanium requires a higher initial investment. If you are buying a titanium exhaust for your car, you might pay $2,000 instead of $800 for stainless steel. The value comes if you are racing and need to save weight, or if you live on the coast and want an exhaust that will never rust out.

For everyday items, stainless steel offers incredible value. A stainless steel cooking pot will last a lifetime for a fraction of the price of titanium cookware. Unless the specific properties of titanium (weight savings, bio-compatibility) are required, stainless steel is usually the smarter financial choice.

Titanium vs Stainless Steel in Everyday Life

You likely encounter the stainless steel vs titanium battle daily without realizing it.

- Jewelry: If you wear a wedding band that feels nonexistent on your finger, it’s likely titanium. If you like the feeling of “heft” in a luxury watch, you probably prefer stainless steel.

- Kitchen: Professional chefs prefer stainless steel pans for their durability and heat retention properties (often with an aluminum core). Titanium pans exist but are mostly used for camping due to their lightness, as they don’t distribute heat as evenly as steel composites.

- Tools: Your wrench set is likely Chrome Vanadium or Stainless Steel. Titanium tools are rare and reserved for environments (like MRI rooms) where magnetic tools are dangerous.

FAQs About Titanium and Stainless Steel

Q1: Does stainless steel last as long as titanium?

In standard indoor environments, both can last indefinitely. However, in harsh outdoor or marine environments, titanium will last significantly longer as it does not suffer from pitting or crevice corrosion like stainless steel eventually does.

Q2: How to tell titanium from stainless steel at home?

The easiest way is the weight test. Compare the item to a similar-sized steel object; if it feels startlingly light, it’s likely titanium. You can also look for the darker, gunmetal gray color compared to the bright silver of steel.

Q3: Which metal is better for jewelry?

If you have sensitive skin or metal allergies, titanium is better because it is hypoallergenic. If you want a ring that can be resized easily or has a high-shine platinum look, stainless steel (or precious metals) is better. Titanium is notoriously difficult to resize.

Q4: Is titanium worth the extra cost?

It is worth it if you need the specific benefits: lightness, extreme corrosion resistance, or non-magnetic properties. For general structural use or kitchenware, the extra cost usually isn’t justified.

Q5: Can stainless steel rust easily compared to titanium?

“Easily” is relative. Compared to regular iron, stainless steel is very rust-resistant. However, compared to titanium, yes—stainless steel can rust if the protective chromium layer is damaged or overwhelmed by salt/chemicals. Titanium effectively does not rust.

How to Choose Between Titanium and Stainless Steel

Deciding between these two super-metals comes down to four factors:

- Weight: If the application flies, races, or hangs on your body all day, titanium wins.

- Durability & Environment: If it will be submerged in seawater or exposed to harsh chemicals, titanium is the safer bet. For general toughness in a workshop or kitchen, stainless steel is more than adequate.

- Cost: If budget is a primary concern, stainless steel is almost always the right answer.

- Appearance: If you want a mirror polish, go with stainless steel. If you want a cool, matte industrial look or custom anodized colors, go with titanium.

Conclusion

The battle of titanium vs stainless steel doesn’t have a single winner—each excels in its own domain. Titanium stands out for high-performance, lightweight applications, and extreme environmental conditions. It’s the premium choice for those who prioritize strength and durability, regardless of cost.

On the other hand, stainless steel continues to be the backbone of modern industry—durable, versatile, and cost-effective. Whether you’re constructing a building, crafting tools, or outfitting your kitchen, stainless steel delivers reliable performance at a great value. For projects requiring expert handling and precision, consulting trusted steel fabricators in Toledo, Ohio can ensure your materials are fabricated to perfection.